Rotary Screw Air Compressors: Cost vs Performance Analysis

Understanding Rotary Screw Air Compressors

Rotary screw air compressors operate through a unique mechanism where a pair of helical-shaped screws rotates within a housing, compressing air as the screws advance. This innovative design offers numerous advantages, including higher efficiency, better durability, and consistent pressure levels. Constructed from high-quality materials such as polyurethane and steel, they are built to withstand heavy-duty applications, making them ideal for demanding environments.

Cost Analysis

The initial investment in a rotary screw compressor can be higher due to its acquisition price and installation costs. However, the long-term operational efficiency and lower maintenance requirements often offset these initial expenses. Key cost factors include:

- Acquisition and Installation: Initial costs are generally higher compared to piston compressors. These expenses include the purchase of the compressor itself, installation labor, and any necessary site modifications. However, the robust design and fewer moving parts can reduce the overall cost of ownership over time.

- Operational Expenses: Lower energy consumption translates into lower utility bills. Rotary screw compressors are known for their high volumetric efficiency, meaning they can produce more air per cubic foot of intake air, reducing the overall power required. For instance, a manufacturing facility reported a 12% reduction in energy costs after switching to rotary screw compressors.

- Maintenance Costs: Regular maintenance is crucial but can be more manageable and less frequent than with piston compressors. The compressors have fewer moving parts and are built to last longer, leading to reduced downtime and maintenance costs.

Over time, the cumulative savings from reduced maintenance and operational costs can lead to a significant return on investment (ROI). According to a recent study, businesses have reported a 20% reduction in operational costs over five years, highlighting the financial benefits of these compressors. This data underscores the value of investing in rotary screw air compressors for long-term cost savings.

Performance Analysis

Key performance metrics for rotary screw compressors include:

- Pressure Levels: They maintain consistent pressure levels, crucial for many industrial processes. This consistency ensures that pneumatic tools and machinery operate at peak efficiency, reducing the likelihood of breakdowns and downtime.

- Power Consumption: Higher volumetric efficiency means less power is needed to achieve the desired output. This not only reduces energy consumption but also lowers the carbon footprint of the facility. For example, a construction site saw a 10% increase in production efficiency due to consistent air pressure from the compressor.

- Durability: They are designed to handle fluctuating loads better than piston compressors, reducing the likelihood of breakdowns. This robustness makes them ideal for applications with varying demand, ensuring continuous and reliable operation.

Compared to piston compressors, rotary screws offer higher efficiency and more consistent performance, albeit at a higher initial cost. This makes them particularly suitable for applications requiring high efficiency and durability.

ROI Evaluation

The return on investment (ROI) for rotary screw compressors can be substantial. Energy efficiency reduces utility bills, and their longer lifespan minimizes downtime. For instance, a food processing plant reported a 15% reduction in energy consumption and noise levels, enhancing workers’ productivity. Another construction site saw a 10% increase in production efficiency due to consistent air pressure from the compressor. These real-world examples highlight the tangible benefits of these compressors.

Case Studies

Real-world examples further illustrate the benefits of rotary screw compressors. In a food processing plant, a rotary screw compressor reduced energy consumption by 15% and noise levels, enhancing workers’ productivity. Another construction site saw a 10% increase in production efficiency due to consistent air pressure from the compressor. These case studies demonstrate how rotary screw compressors can deliver significant improvements in both performance and cost.

Comparative Analysis

While both piston and rotary screw compressors serve similar purposes, their performance and suitability vary. Piston compressors are better suited for high-capacity, low-pressure applications, whereas rotary screws excel in moderate to high-pressure scenarios. Key differences include:

- Noise Levels: Rotary screws can be noisier, especially in higher pressure applications, although new technologies are reducing this. A recent study showed that modern rotary screw compressors offer a 25% reduction in noise levels compared to their predecessors.

- Efficiency: Rotary screws offer higher volumetric efficiency and are more robust in handling fluctuating loads. This makes them ideal for applications with varying demand, ensuring consistent performance.

Future Trends

Emerging trends in the air compressor industry include the use of electric rotary screw compressors, which reduce operational noise and energy consumption. Advanced lubrication systems and smart monitoring technologies are also being integrated, enhancing reliability and efficiency. AI-driven controls promise further optimization, aligning with future industrial demands.

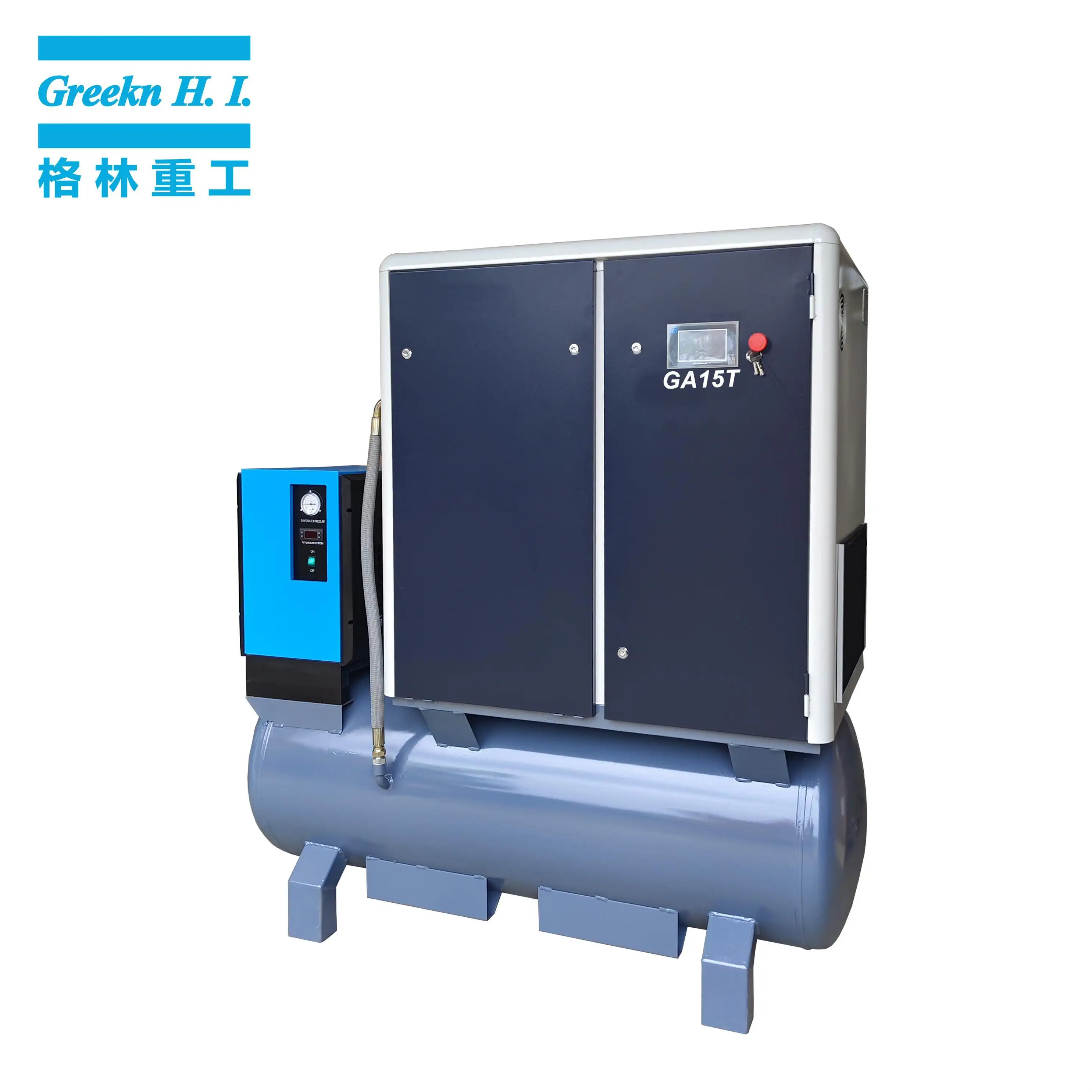

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: evelynli@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.