Revolutionize Your Compressing Needs with Reliable Rotary Screw Air Compressors

In todays fast-paced and competitive industrial landscape, the efficiency and reliability of equipment are paramount. Air compressors, as essential tools in manufacturing and industrial processes, play a pivotal role in powering machinery, driving processes, and ensuring productivity. However, choosing the right air compressor can be a challenging task, as there are numerous options available, each with its own set of features and benefits.

The Benefits of Rotary Screw Air Compressors

Rotary screw air compressors offer a host of advantages that make them an indispensable part of any industrial setup. One of the most significant benefits is their energy efficiency. Unlike traditional air compressors, which often consume a substantial amount of energy, rotary screw compressors are designed to minimize energy waste. This not only reduces operational costs but also contributes to a lower carbon footprint, making them a responsible choice for environmentally conscious businesses.

Another key advantage of rotary screw air compressors is their reliability. These machines are built to last, with robust construction and advanced components that ensure they can handle heavy-duty operations without compromising on performance. Whether its powering large machinery or compressing air for industrial processes, rotary screw compressors deliver consistent results, minimizing downtime and ensuring smooth operations.

The cost-effectiveness of these compressors is also noteworthy. While initial investment may be higher compared to smaller compressors, rotary screw air compressors offer long-term savings due to their efficiency and durability. Lower maintenance costs, reduced energy consumption, and extended operational lifespans all contribute to making these compressors a cost-effective solution for businesses.

How Rotary Screw Air Compressors Work: A Technical Deep Dive

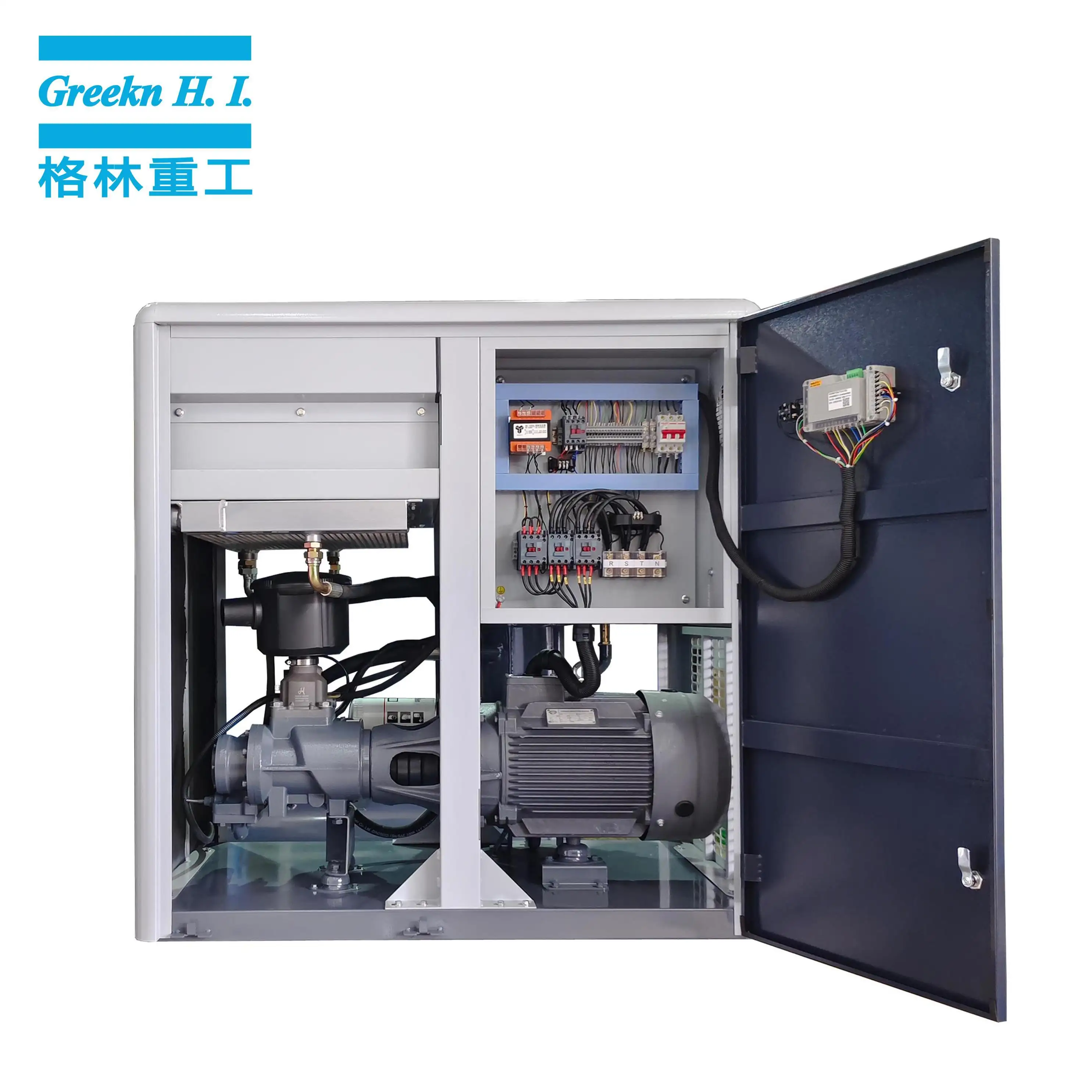

Understanding the inner workings of rotary screw air compressors is essential to fully appreciate their benefits. These machines operate on a unique principle that sets them apart from traditional reciprocating compressors. The core of a rotary screw compressor consists of a motor driving a pair of rotors, which are enclosed within an air chamber. As the motor rotates, the rotors spin inside the chamber, creating a seal that traps the compressed air.

One of the most innovative aspects of rotary screw compressors is their ability to handle high-pressure applications. The rotors are designed with precision engineering, ensuring minimal leakage and efficient air compression. The oil-cooled system also helps in dissipating heat, maintaining optimal performance under various conditions.

The cooling mechanism in these compressors is equally impressive. Modern models incorporate advanced cooling systems, which not only extend the lifespan of the machine but also enhance its efficiency. The combination of precise compression, efficient cooling, and durable components makes rotary screw air compressors a powerhouse of reliability and performance.

Why the "Best Rotary Screw Air Compressor" Matters

Selecting the best rotary screw air compressor is a decision that requires careful consideration of several factors. Each compressor has its unique features, and what works for one application may not be suitable for another. The "best" compressor is determined by a combination of efficiency ratings, operating range, and warranty, ensuring that it meets the specific needs of the business.

High efficiency ratings are crucial for businesses that are committed to reducing energy costs and environmental impact. These ratings are typically based on the compressors ability to convert electrical energy into compressed air with minimal energy loss. Additionally, the operating range of a compressor, including its minimum and maximum pressure capabilities, ensures that it can handle the demands of the specific industry it is serving.

Warranty and after-sales support are also important considerations. A reliable compressor with a comprehensive warranty reduces the risk of unexpected breakdowns and ensures that the business has access to timely repairs and services. These factors, along with the overall build quality and durability, determine whether a rotary screw air compressor is the right choice for a business.

Case Studies: Real-World Success Stories with Rotary Screw Air Compressors

To better illustrate the benefits of rotary screw air compressors, lets look at some real-world success stories. Companies across various industries have adopted these compressors, experiencing significant improvements in efficiency, productivity, and operational performance.

One notable case involves a manufacturing facility that switched from traditional compressors to a high-capacity rotary screw air compressor. With the new equipment, the facility was able to reduce its energy consumption by 25%, leading to substantial savings on electricity bills. The compressors reliability also resulted in fewer downtime incidents, minimizing disruptions to production schedules.

Another example comes from the automotive industry, where a major parts manufacturer upgraded its air compression system to a rotary screw compressor. The upgrade not only improved the quality of compressed air but also enhanced the performance of the machinery it powered. The resulting productivity gains allowed the company to meet higher demand while maintaining tight deadlines.

These case studies highlight the transformative impact that rotary screw air compressors can have on industrial operations. By adopting these machines, businesses can achieve higher efficiency, reduce costs, and improve overall productivity, setting them apart in a competitive market.

Comparative Analysis: Rotary Screw vs. Other Compressor Types

To fully appreciate the value of rotary screw air compressors, its essential to compare them with other types of compressors. While there are many options available, including reciprocating and centrifugal compressors, rotary screw air compressors offer distinct advantages that make them a superior choice in many scenarios.

Reciprocating compressors, which have been the standard for decades, are known for their durability and cost-effectiveness. However, they often struggle with high-pressure applications and can be less efficient compared to rotary screw compressors. On the other hand, centrifugal compressors are lighter and more compact, making them ideal for mobile operations. However, they tend to be less efficient and more prone to vibration, which can impact performance in demanding environments.

Rotary screw air compressors strike a balance between efficiency, durability, and versatility, making them a top choice for businesses that require robust and reliable compressing solutions. They are particularly well-suited for industries with high air consumption demands, such as manufacturing, construction, and mining, where consistent and efficient air supply is critical.

Choosing the Right Model for Your Needs

Selecting the right rotary screw air compressor is a critical step in ensuring optimal performance. To make an informed decision, businesses should consider several factors, including their air consumption requirements, operating environment, and budget constraints.

One important factor is the compressors air consumption, which is measured in cubic feet per minute (CFM). Different industries have varying CFM requirements, so its essential to choose a compressor that can meet these specific needs. For instance, a compressor designed for high-pressure applications may have a higher CFM output compared to one used in low-pressure scenarios.

The operating environment is another crucial consideration. Rotaries screw compressors are typically designed to handle a wide range of conditions, including extreme temperatures, varying pressures, and noisy environments. Businesses should ensure that the chosen compressor is compatible with their specific operational requirements, such as noise levels and temperature fluctuations.

Budget is also a key factor in the purchasing process. While higher-priced models may offer additional features and benefits, its important to strike a balance with the available budget. Businesses should research the market and compare different options to identify the best value for their needs.

To assist in the decision-making process, weve compiled a checklist of questions to ask when selecting a rotary screw air compressor:

- What is the minimum and maximum pressure range required for my application?

- What is the CFM output of the compressor, and is it suitable for my needs?

- Is the compressor designed for noisy or quiet operation?

- What is the warranty period and support availability?

- Is the compressor energy-efficient, and what is its efficiency rating?

By addressing these questions, businesses can make a well-informed decision and select the best rotary screw air compressor for their operations.

Maintenance and Tips for Extending Compressor Lifespan

Maintenance is a critical aspect of ensuring the longevity and efficiency of a rotary screw air compressor. Proper maintenance practices can help minimize downtime, reduce energy consumption, and extend the lifespan of the machine. Here are some key tips for maintaining rotary screw air compressors effectively:

Regular Oil Changes: Rotary screw compressors are oil-cooled, so regular oil changes are essential to prevent overheating and ensure optimal performance. Check the oil level and replace the oil as recommended by the manufacturer.

Filter Cleaning: Air filters are a crucial component of the compression system. Regular cleaning or replacement of filters ensures air quality and prevents blockages, which can lead to operational issues.

Seal Inspection and Replacement: seals are a common point of failure in compressors. Regular inspection and replacement of seals can help prevent leaks and extend the machines lifespan.

Cooling System Check: The cooling system in rotary screw compressors plays a vital role in maintaining performance. Ensure that the cooling fan is running and that there are no blockages in the cooling system.

Regular Inspections: Conduct routine inspections of the compressor and its components to identify and address potential issues before they escalate. This proactive approach can help prevent unexpected breakdowns and reduce maintenance costs.

By following these maintenance practices, businesses can ensure that their rotary screw air compressors operate efficiently and last for years to come.

Environmental Impact and Sustainability Considerations

The environmental impact of air compressors is another critical factor to consider, especially as businesses strive to adopt sustainable practices. Rotary screw air compressors offer a greener alternative to traditional compressors, with lower energy consumption and reduced emissions. By adopting these machines, businesses can contribute to a more sustainable future while reducing their carbon footprint.

Many industries are now prioritizing sustainability and green practices, making rotary screw air compressors a popular choice among eco-conscious businesses. Additionally, the oil-cooled system of these compressors helps in reducing the overall environmental impact by minimizing the need for additional cooling infrastructure.

As businesses continue to emphasize sustainability, the adoption of advanced technologies like rotary screw air compressors is becoming a key strategy for reducing their ecological footprint. By investing in sustainable solutions, companies can not only save money but also align with global efforts to combat climate change.

Why Rotary Screw Air Compressors Are the Future of Compressing Needs

In an era where efficiency, reliability, and sustainability are key priorities, rotary screw air compressors are no longer just machines but a symbol of progress and innovation. These compressors are revolutionizing the way industries approach their compressing needs, offering a combination of energy efficiency, durability, and versatility that sets them apart from traditional solutions.

As businesses continue to demand higher performance and lower operational costs, the adoption of rotary screw air compressors is becoming a necessity. By investing in these machines, companies can achieve significant cost savings, reduce their environmental impact, and enhance productivity, paving the way for a more sustainable and efficient future.

In conclusion, rotary screw air compressors are not just a trendthey are a proven solution for meeting the demands of modern industry. With their advanced technology, reliable performance, and commitment to sustainability, these compressors are shaping the future of compressing needs and setting new standards for business excellence.

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.