15 Tips to Choose the Right Rotary Screw Air Compressor for Your Business

Air compressors are essential tools in industrial operations, providing the necessary compressed air for a wide range of tasks. They play a vital role in manufacturing, logistics, and construction by powering various machinery and tools. When it comes to reliability and efficiency, rotary screw air compressors stand out. These compressors are known for their high capacity, durability, and quieter operation compared to other types like piston or reciprocating models.

Key Advantages of Rotary Screw Air Compressors

- High Efficiency: Rotary screw compressors are designed to operate efficiently, consuming less energy than their counterparts while maintaining consistent air pressure.

- Durability: With fewer moving parts, these compressors are less prone to wear and tear, leading to longer lifespans.

- Quiet Operation: They produce less noise, making them suitable for environments where quiet operation is essential.

- Compact Design: Modern rotary screw compressors are designed to be compact, allowing them to fit in confined spaces.

Case Study: Boosting Productivity with the Right Compressor

A manufacturing facility in the automotive industry faced frequent downtime due to unreliable air compressors. After upgrading to a rotary screw compressor, they reported a significant increase in productivity and reduced maintenance costs. The compressor provided consistent air pressure, leading to smoother operations and fewer production disruptions.

Understanding the Basics of Rotary Screw Air Compressors

Explanation of the Working Principle

A rotary screw air compressor works by using two intermeshing helical screws inside a cylinder. The screws spin within a sealed housing, compressing the incoming air and forcing it out at high pressure. This process is continuous, resulting in a steady flow of air.

Types of Rotary Screw Air Compressors

- Fixed Speed Compressors: These operate at a constant RPM and are best suited for environments with stable air demand.

- Variable Speed Compressors: These adjust their speed based on the load, offering better energy efficiency and lower noise levels.

Key Factors to Consider When Choosing the Right Rotary Screw Air Compressor

Load Requirements

Understanding your businesss air demand is crucial. Calculating the cubic feet per minute (CFM) needed for your operations will help you select the right size compressor.

Efficiency and Energy Consumption

Compare the energy efficiency of different models. Look for compressors with ENERGY STAR ratings and energy efficiency indicators. For instance, the Airtronic VSR range features advanced energy-saving technologies that can reduce energy consumption by up to 30%.

Reliability and Maintenance

Choose a compressor with a robust warranty and regular maintenance requirements. A well-maintained compressor will operate more reliably and cost-effectively over time. Companies like Ingersoll Rand offer comprehensive maintenance programs with regular scheduled services.

Noise Levels and Installation Space

Rotary screw compressors are generally quieter than piston models. Ensure you have enough space for installation and operation. A well-planned installation can prevent future operational issues and ensure compliance with local regulations.

Maintenance and Cost Considerations

Regular Maintenance Practices

Proper maintenance can extend the life of your compressor and prevent unexpected breakdowns. Regular tasks include oil changes, air filter cleaning, and checking for leaks. A well-maintained compressor can last up to 50,000 hours or more.

Total Cost of Ownership (TCO)

Consider the long-term financial impact. While high upfront costs may be higher for energy-efficient compressors, they can save significant amounts in energy bills and maintenance costs over their lifespan. For example, a well-maintained GLS rotary screw compressor can reduce energy consumption by 25% compared to standard models.

Energy Efficiency Standards

The Department of Energy (DOE) sets efficiency standards for air compressors. Compressors that meet these standards, such as the ones by Alsing, can save businesses money and reduce their environmental footprint.

Selecting the Best Rotary Screw Air Compressor for High-Pressure Applications

Advantages of High-Pressure Models

High-pressure rotary screw compressors are designed to handle demanding applications requiring consistent, high-pressure air. They are ideal for industries like oil and gas, aviation, and heavy-duty manufacturing.

Applications and Key Features

Applications that demand high pressure, such as spray painting or hydraulic systems, benefit from robust features like overload protection and high torque. Models like the Krieg HP series offer long-lasting and efficient performance, making them ideal for ongoing, high-demand operations.

Maximizing Efficiency and Performance

Strategies for Optimization

Optimize your air compressor by using advanced control systems. Variable speed drives can adjust the compressors output based on the actual demand, reducing energy consumption and lowering noise levels. Additionally, regular performance monitoring can help identify potential issues early.

Control Panel Use

Proper use of the control panel can improve performance and reduce downtime. Utilize features like automatic shut-off and pressure regulation to ensure consistent performance. A well-calibrated control panel can save up to 10% in energy costs.

Benefits of Advanced Control Systems

Advanced control systems not only reduce energy consumption but also enhance reliability. Features like real-time monitoring and predictive maintenance can alert you to potential issues before they escalate.

Comparing Rotary Screw Air Compressors with Other Options

Comparative Analysis

While rotary screw compressors are highly efficient, they may not be the best choice for every application. Compare the features, efficiency, and reliability of different compressor types to find the best fit for your business. For instance, piston compressors might be more economical for small operations but less efficient and louder than rotary screw models.

Technological Advancements

Modern rotary screw compressors incorporate numerous technological advancements, such as variable frequency drives (VFDs), which can significantly improve energy efficiency and overall performance. Manufacturers like Atlas Copco offer state-of-the-art models that integrate these technologies seamlessly.

Long-Term Benefits

Choosing a high-quality rotary screw air compressor can provide long-term benefits. Reliable compressors like those from Quincy Compressor offer superior performance and durability, ensuring consistent operations and reduced downtime.

Technical Specifications and Performance Indicators

Key Technical Specifications

When choosing a rotary screw air compressor, look for specifications such as CFM, horsepower, and maximum pressure output. These metrics help you determine the compressors capacity to meet your businesss air demand. For instance, a 500 CFM compressor would be suitable for a mid-sized manufacturing facility.

Performance Indicators

Monitor performance indicators like energy efficiency ratings (EER) and isentropic efficiency to ensure the compressor is operating at peak performance. A compressor with an EER of 1.7 or higher can save substantial energy costs.

Selection of Appropriate Specifications

Selecting the right specifications is crucial. A well-chosen compressor can reduce energy consumption by up to 20%, leading to significant cost savings.

Customer Support and Warranty Considerations

Importance of Customer Support

Reliable customer support can make a significant difference in long-term satisfaction. Manufacturers like Komatsu offer comprehensive support teams that can provide quick solutions to any problems you might encounter.

Warranty Terms and Coverage

Ensure you understand the warranty terms, including coverage, duration, and any conditions. A warranty that covers components like the motors and compressors can provide peace of mind and prevent unexpected costs.

Real-World Impact of Customer Support

A business that experienced a compressor failure found prompt and effective support from OEMs like PFAU Compressors, which helped them get back to operations quickly and minimize downtime.

Sizing and Sourcing the Right Rotary Screw Air Compressor

Accurate Sizing

Proper sizing is crucial for ensuring the compressor can meet your businesss air demand without being over-engineered. Use load calculations to determine the appropriate size.

Tips for Sourcing

When sourcing a compressor, consider factors like the manufacturers reputation, reviews, and warranty coverage. Testing the compressor in your specific environment before committing can help ensure a good fit.

Common Pitfalls

Failing to accurately size the compressor can lead to over- or under-sizing. Over-sizing can increase operational costs, while under-sizing can cause frequent breakdowns. Always consult with a professional to ensure the right fit.

Environmental Impact and Sustainability

Environmental Impact

Rotary screw air compressors are known for their lower noise levels and lower emissions compared to other types. They also help reduce a businesss carbon footprint. For example, a compressor that meets Energy Star standards can save up to 30% in energy consumption and substantially reduce greenhouse gas emissions.

Sustainability Features

Modern compressors often incorporate eco-friendly features like air separation units and heat recovery systems. These features not only help the environment but also can save money on energy costs.

Regulatory Compliance

Compliance with environmental regulations is essential. Choosing a compressor that meets relevant standards, such as the ENERGY STAR program, can help businesses stay in line with regulatory requirements and potentially qualify for incentives.

Professional Installation and Considerations

Importance of Professional Installation

Professional installation is crucial for ensuring the compressor operates efficiently and is properly aligned with your facility. A skilled installer can handle the complex components and ensure the compressor meets all local codes and standards.

Installation Best Practices

Before installing, consult with a professional to determine the right size, type, and placement. Proper installation can prevent breakdowns and optimize performance. For instance, installing a compressor from Kaeser directly aligned with the manufacturers specifications can ensure long-term reliability.

Common Mistakes

Failing to follow proper installation procedures can lead to issues like inadequate ventilation, improper alignment, or incorrect connections. Always ensure the installation complies with manufacturer guidelines and relevant codes.

Real-Life Examples and Applications

Success Stories

A manufacturing facility that upgraded to a high-pressure rotary screw compressor saw a 25% reduction in energy costs and a 20% increase in operational efficiency. The compressor provided consistent air pressure, leading to smoother operations and fewer production disruptions.

Case Studies

Another example is a logistics company that needed a reliable air compressor for its large fleet of trucks. After testing several models, they chose a rotary screw compressor from Seeingey. The compressor met their needs, providing consistent air for pneumatic tools and ensuring the trucks were always ready for use.

Additional Tips

Staying Informed

Stay informed about industry trends and advancements. Regularly reading industry publications and attending seminars can provide valuable insights. Manufacturers like Quincy Compressor frequently offer webinars and workshops that can help businesses stay up-to-date.

Online Resources

Utilize online guides, forums, and manufacturer websites to learn more about rotary screw air compressors. Resources like the Air Conditioning Contractors of America (ACCA) and the Compressed Air and Gas Institute (CAGI) offer valuable information and certification programs.

Customer Reviews

Reading customer reviews can provide practical insights into the performance and reliability of different compressors. Platforms like Trustpilot and Amazon offer user reviews that can help you make an informed decision.

Conclusion

Choosing the right rotary screw air compressor is a critical decision that can impact your businesss efficiency, productivity, and sustainability. By considering factors like load requirements, efficiency, reliability, and environmental impact, you can select a compressor that meets your needs and delivers long-term value. With the right compressor, you can reduce costs, improve performance, and contribute to a more sustainable future.

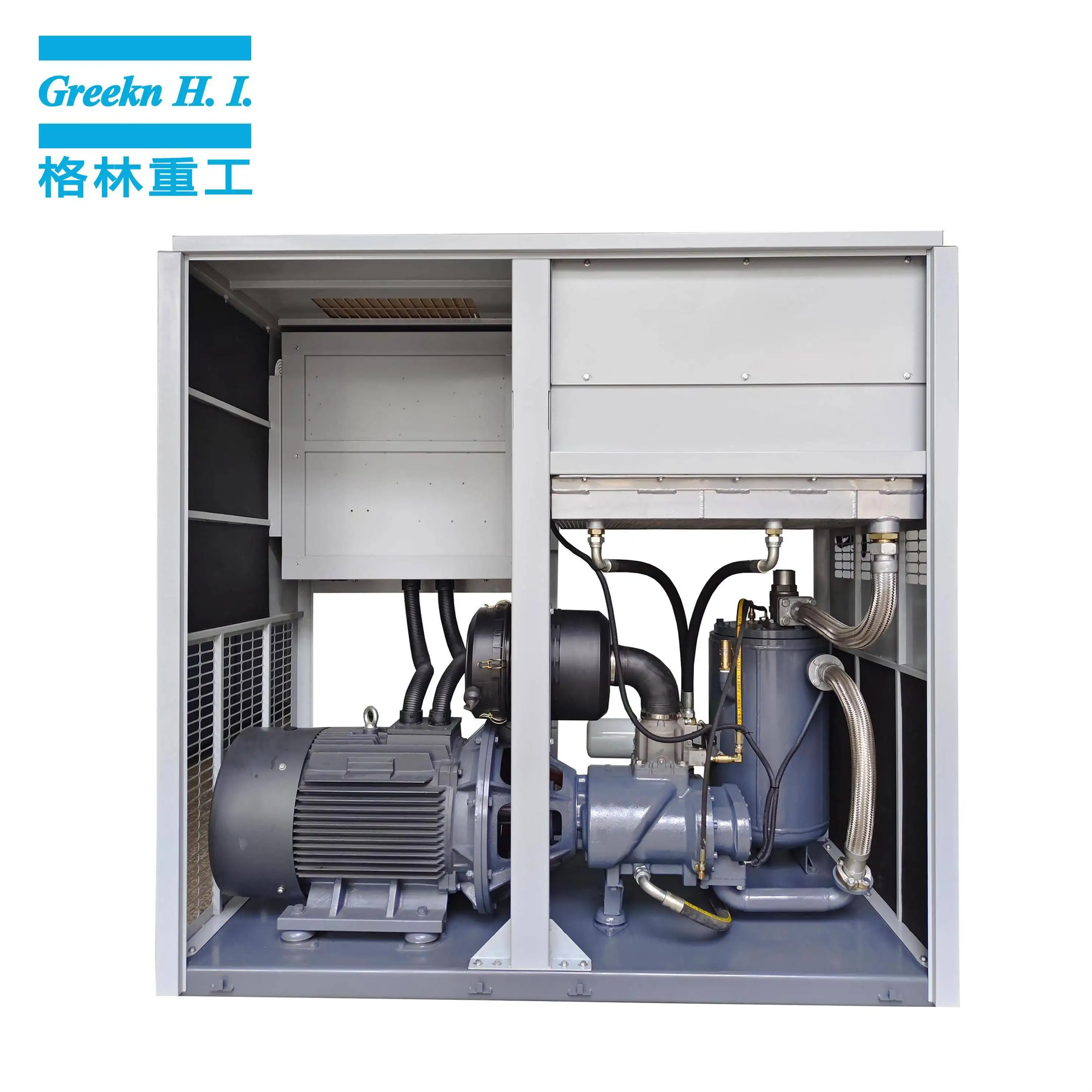

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.