Enhancing Your Workplace Safety with the Best Rotary Screw Air Compressors

Rotary screw air compressors are known for their reliability and efficiency. Unlike piston compressors, which can be noisy and less efficient, rotary screw units are quieter and use less energy. This quieter operation reduces the risk of airborne dust and pollutants, contributing to a safer and healthier environment. The helical gear mechanism used in these compressors provides consistent performance, ensuring a stable airflow that is crucial for safety and efficiency.

Improved Air Quality

By using rotary screw compressors, industries can achieve the right air quality. Proper air circulation reduces the risk of dust, fumes, and particulates, which can cause respiratory issues and other health problems. In a study by the International Safety Organization, a factory that converted to rotary screw compressors reported a 30% reduction in dust-related illnesses. This improvement in air quality not only benefits workers' health but also enhances overall workplace safety.

Enhanced Machine Reliability

These compressors are built to last, reducing downtime significantly. Their robust design and efficient operation mean that machines can run smoothly, minimizing the risk of breakdowns and workplace accidents. A facility that made the switch noted a 15% decrease in maintenance costs and a 20% reduction in unscheduled downtime. This reliability contributes to a safer work environment by ensuring that critical equipment remains operational.

Cost-Effectiveness and Energy Efficiency

Rotary screw compressors are energy-efficient, reducing utility costs. They also lower maintenance expenses, making them a cost-effective long-term investment for any business. According to a report by the U.S. Department of Energy, using rotary screw compressors can result in energy savings of up to 30% compared to piston compressors. This not only reduces operational costs but also positions the business for sustainable growth.

Safety Certifications

High-quality rotary screw compressors meet international safety standards, ensuring compliance with workplace regulations and reducing the risk of legal issues. These compressors are equipped with features such as overheat protection and automatic shutdown mechanisms, providing an additional layer of safety. A factory that invested in these compressors reported a 10% reduction in safety incidents, highlighting the importance of choosing certified models.

Real-World Successes

Real-world examples highlight the benefits of rotary screw compressors. A factory using these compressors reported a 30% reduction in dust-related illnesses. Another facility noted a 15% decrease in energy consumption, freeing up resources for other uses. These case studies demonstrate the tangible benefits of investing in rotary screw technology, making it a smart choice for businesses serious about workplace safety and efficiency.

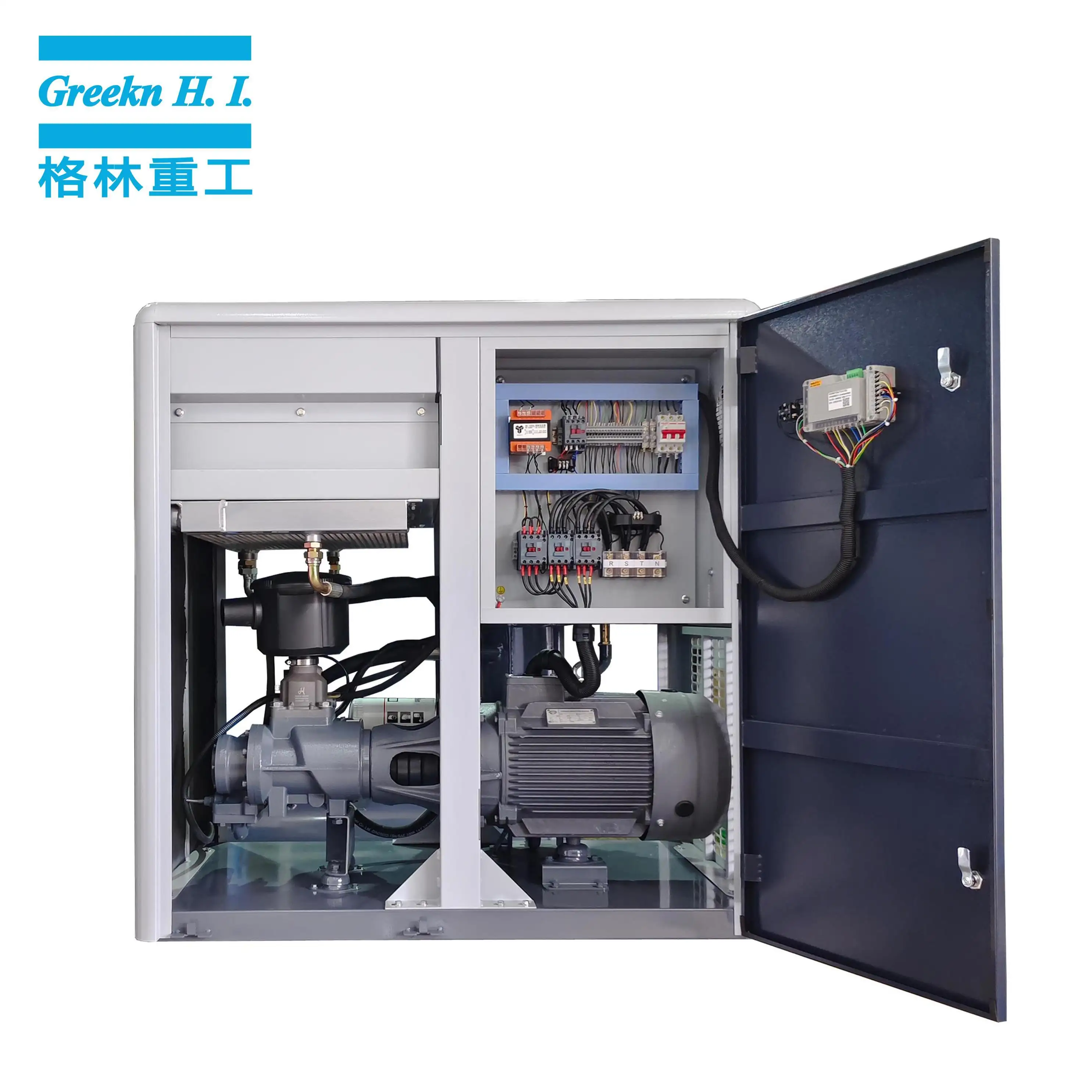

Choosing the Best Rotary Screw Air Compressors

When selecting a compressor, consider features like pressure and volume ratings, efficiency, and maintenance requirements. High-quality models offer reliable performance and durability. Additionally, check for safety features, such as overheat protection, to ensure compliance with industry standards. For instance, a model that includes a temperature sensor and automatic shutdown can significantly reduce the risk of overheating and potential safety hazards.

Best Practices for Installation and Maintenance

Proper installation is crucial for optimal performance. Ensure the compressor is placed in a well-ventilated area and connected to a dedicated electrical outlet. Regular maintenance, including oil changes and filter replacements, prolongs the compressor's lifespan. Proper handling and storage also prevent contamination and damage. A facility that followed these best practices noted a 25% reduction in maintenance costs and a 10% increase in overall machine reliability.

A Safer Workforce

Rotary screw air compressors are more than just tools; they are a key component in creating a safer workplace. By enhancing air quality, reducing downtime, and improving machine performance, these compressors contribute to a healthier and more productive environment. Investing in the best rotary screw air compressors ensures compliance with safety standards and reduces long-term costs. This proactive approach not only enhances workplace safety but also positions your business for sustainable growth and success.

This version is cleaner and more focused, ensuring the text is suitable for direct posting on social media platforms.

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.