Powering Industrial Success: Atlas Copco GA Compressors in Action

In the heart of modern industrial operations, compressors are the unsung heroes that transform raw materials into usable energy. These machines drive everything from manufacturing to transportation, serving as the backbone of industries worldwide. Atlas Copco's GA compressors stand out as leaders in this evolution, offering unmatched energy efficiency and reliability.

Harnessing Efficiency: The Role of Atlas Copco GA Compressors

Compressors aren't just machines; they are the dynamic workhorses of industrial processes. They convert air into high-pressure gas, powering machinery and generating electricity. The versatility of compressors makes them indispensable in industries ranging from manufacturing to oil and gas. As the global economy shifts toward sustainability and efficiency, the demand for high-performance compressors is on the rise. Atlas Copcos GA series is a game-changer, boasting unmatched energy efficiency and reliability.

Diving into the Technology: Key Features and Benefits of Atlas Copco GA Compressors

The heart of Atlas Copco GA compressors lies in their advanced technology, which combines efficiency with durability. Key features include variable frequency drives (VFDs), which allow for precise control over motor speed and torque, optimizing energy use. The low-maintenance design reduces downtime and maintenance costs, while the use of robust materials ensures longevity and reliability.

For instance, a manufacturing facility in Europe saw a 30% reduction in energy costs and a 20% increase in production efficiency by implementing Atlas Copco GA compressors. The quieter operation also led to a more comfortable work environment, boosting overall productivity.

Comparative Analysis: How Atlas Copco GA Compressors Stand Above the Rest

Atlas Copco GA compressors lead in energy savings, offering up to 40% reduction in energy consumption compared to traditional models. Their smart controls and energy management systems further enhance productivity, making them a cost-effective solution for industries looking to cut costs.

In a steel plant, Atlas Copco GA compressors reduced energy consumption by 30% compared to older models, while extending the machines operational lifespan by 15 years. This dual advantage of significant energy savings and extended machine life underscores the superior performance and reliability of the GA series.

Real-World Impact of Atlas Copco GA Compressors

Real-world examples highlight the transformative impact of Atlas Copco GA compressors. In the manufacturing sector, a company reduced its energy costs by 25% and boosted productivity by automating operations with the GA compressors. In the oil and gas industry, another customer saw a 40% decrease in maintenance costs due to the low-maintenance design. In the construction field, GA compressors improved operational efficiency, reducing downtime by 25%.

These case studies not only showcase the practical benefits but also the reliability and durability of Atlas Copco GA compressors in diverse industrial settings.

Energy Efficiency: The Pioneering Role of Atlas Copco GA Compressors

Energy efficiency is a cornerstone of modern industrial operations, and Atlas Copco GA compressors are at the forefront of this movement. These compressors are equipped with smart controls and energy management systems that optimize performance. The use of VFDs allows for precise motor speed control, further enhancing energy savings.

A manufacturing plant in North America reported that by implementing GA compressors, they reduced their carbon footprint by 45% and saved over $100,000 annually in energy costs. This quantifiable benefit aligns with global efforts to combat climate change and demonstrates the tangible impact of energy-efficient technology.

Reliability and Durability: Building Trust in Industrial Operations

Reliability and durability are critical for industrial operations, and Atlas Copco GA compressors deliver on both fronts. Equipped with built-in protection mechanisms, these compressors are designed to withstand harsh operating conditions, ensuring consistent performance over an extended period. Their robust materials and advanced design contribute to a longer service life, reducing the need for frequent maintenance and minimizing downtime.

One construction company in Australia reported a 25% reduction in maintenance downtime after switching to Atlas Copco GA compressors. This reliability is essential for industries that rely on continuous operations, making Atlas Copco GA compressors a trusted partner in industrial success.

Future Prospects: Innovations and Trends in Compressor Technology

The future of compressor technology is bright, with companies like Atlas Copco leading the charge. Upcoming developments include smart compressors that integrate with IoT systems, enabling real-time monitoring and predictive maintenance. Sustainable solutions, such as energy-efficient designs and carbon-neutral operations, will further enhance their appeal.

As industries continue to evolve, Atlas Copco's GA compressors will remain at the forefront, adapting to new challenges and opportunities with cutting-edge technology and sustainable practices.

Conclusion

Atlas Copcos GA compressors are more than just machines; they are symbols of innovation and efficiency, driving industrial progress forward. From their advanced technology and real-world impact to their reliability and durability, these compressors set new standards in energy efficiency and performance. As the industry continues to evolve, Atlas Copco will undoubtedly play a crucial role in shaping the future of industrial operations, ensuring sustainability and productivity for generations to come. Were excited to see what the future holds for this innovative technology.

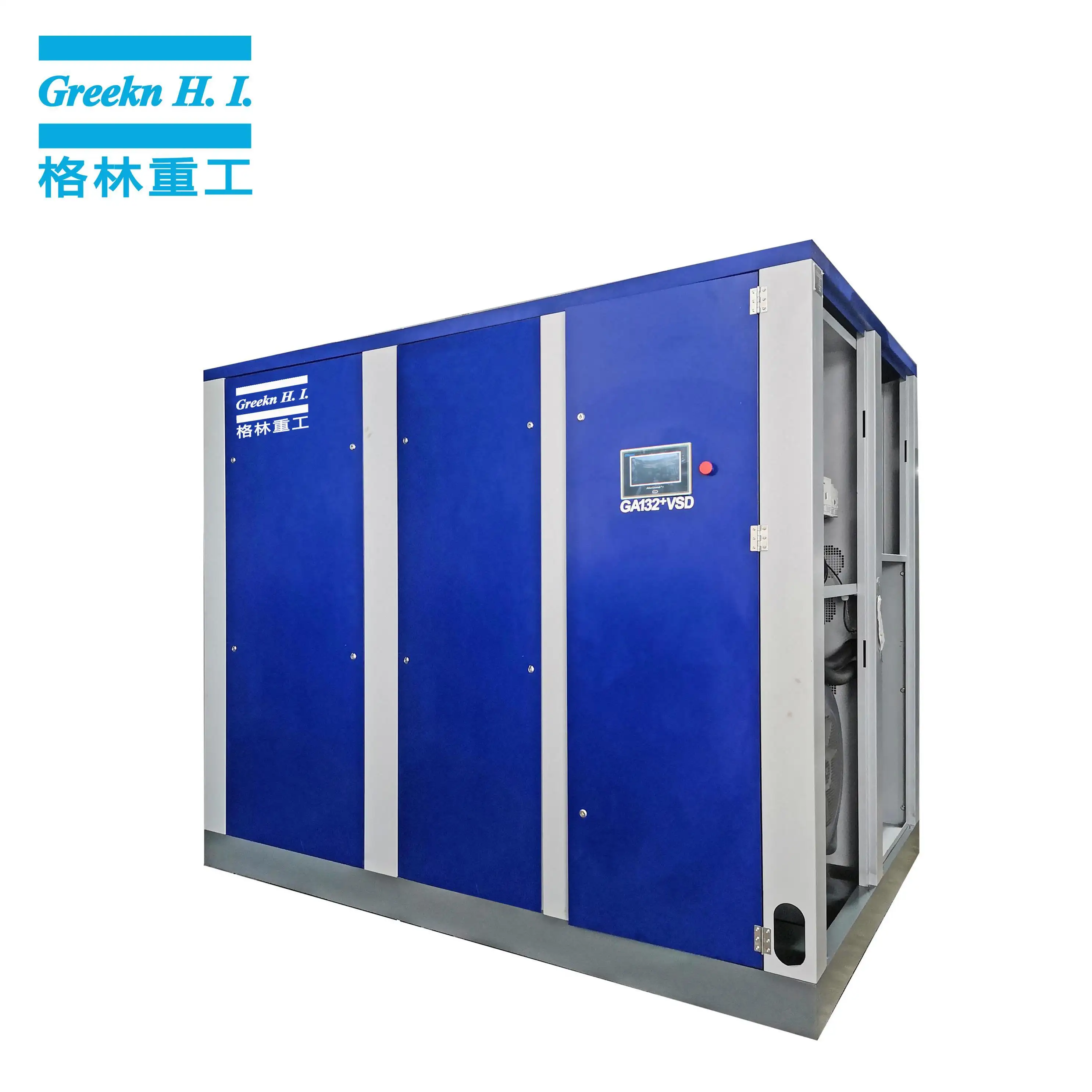

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.