Best Practices for Choosing the Right Atlas Copco GA Compressor

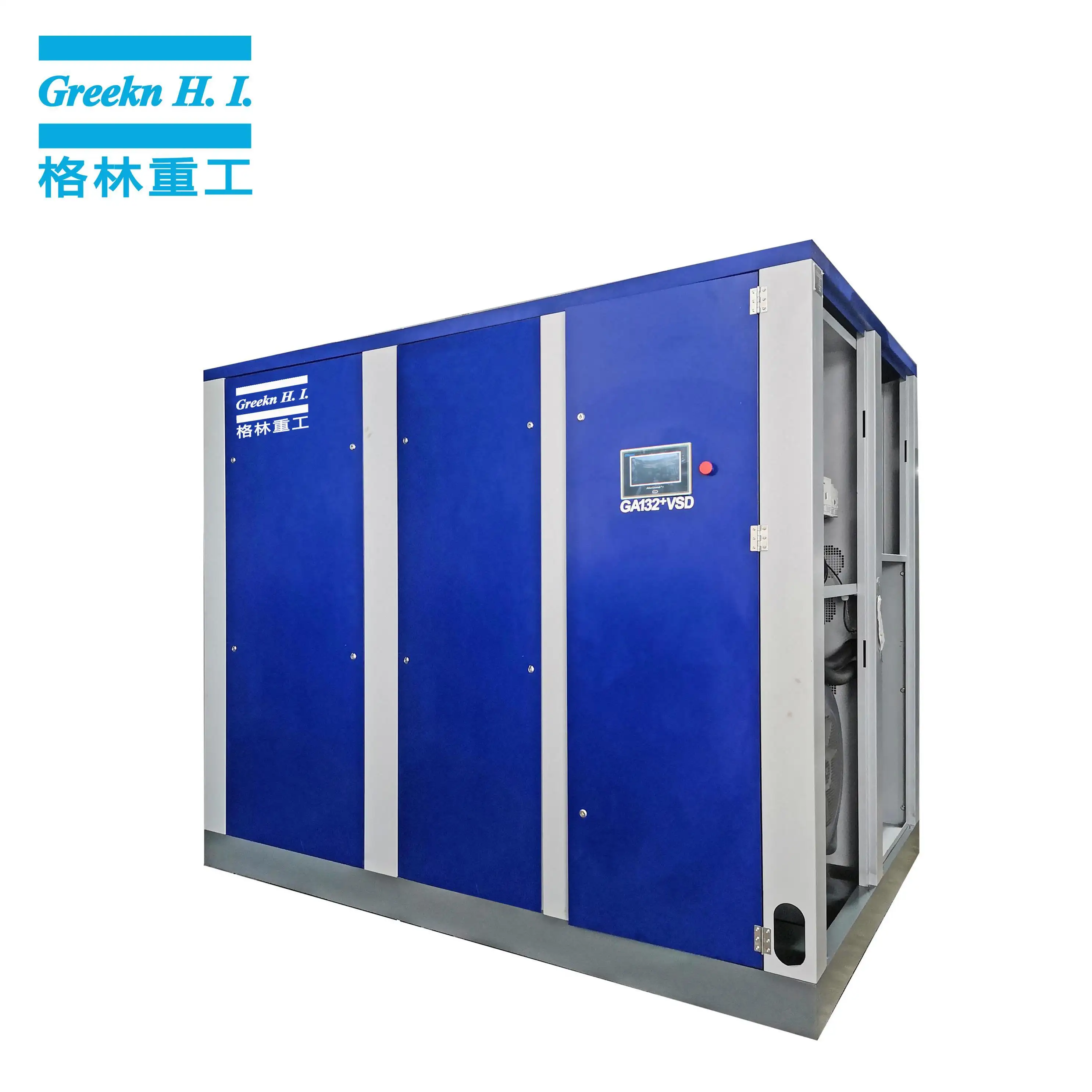

Imagine stepping into a modern industrial setting where every operation is meticulously planned and executed with precision. The Atlas Copco GA compressor is a key component in ensuring reliable and high-quality air supply. Known for their robust design and advanced features, these compressors are ideal for various industries like manufacturing, construction, and chemical processing.

Features and Capabilities of Atlas Copco GA Compressors

The GA series compressors are designed with several advanced features that enhance performance and reliability. Advanced filtration systems ensure that the compressed air is clean and free from contaminants, crucial for industries like pharmaceuticals. For example, a pharmaceutical plant can benefit significantly from GA compressors, ensuring clean and sterile conditions in their production processes.

Energy efficiency is another standout feature. The GA compressors come with smart controls and variable speed drives that optimize performance and reduce energy consumption. Imagine an automotive manufacturing plant using these compressors to power their intricate assembly lines. These intelligent systems adapt to real-time demand, saving energy and extending the compressor's lifespan.

Durability and ease of maintenance are key aspects of the GA series. Regular maintenance intervals and simple diagnostic tools ensure that any issues are identified and resolved quickly. A wind turbine manufacturer that uses GA compressors reports that regular maintenance has significantly reduced operational costs and increased uptime.

Modular design is another advantage, allowing for easy customization to meet specific requirements. For example, a construction company can configure the GA compressor to suit different job sites, providing a flexible air supply system.

Key Factors to Consider

Requirement Analysis: Assess your specific needs, including pressure, flow, and duty cycle. For instance, a bakery might need a compressor for high-pressure environments and frequent starts and stops.

Environmental Considerations: Factors like climate, altitude, and humidity can impact the compressor's performance. A mining company operating in high-altitude regions can benefit from GA compressors designed to operate efficiently at lower air density.

Operational Costs: Evaluate costs, including initial investment, running costs, and total cost of ownership. A food processing plant in a cold region can save on energy usage with GA compressors due to their advanced controls.

Backup and Reliability: Uptime is crucial. The availability of spare parts and a robust maintenance plan can ensure continuous operation. A manufacturing facility that relies on GA compressors can avoid costly downtime.

Choosing the Right Model

The Atlas Copco GA compressors are versatile, suitable for various industries. They can support small-scale operations in a bakery or large-scale production lines in a manufacturing plant. Customization options include different types of air treatment units and control systems tailored to your specific needs.

Installation and Maintenance

Installation Guidelines: Place the compressor in a stable, level, and well-ventilated area. A pharmaceutical plant should ensure the compressor is in a location that maintains consistent temperatures and minimizes dust and debris.

Maintenance Checklist: Regularly check oil levels, replace filters, and inspect components. A textile manufacturing company has reported a 20% reduction in maintenance costs by following a strict maintenance schedule.

Case Studies

Pharmaceutical Plant: A food processing plant in Germany reported a 30% reduction in energy consumption after switching to Atlas Copco GA compressors. They previously faced high energy bills and frequent compressor breakdowns.

Construction Company: A construction company in the United States used GA compressors to support their heavy machinery operations. The compressors provided consistent and reliable air supply, reducing downtime and improving productivity.

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.