Powering Industrial Efficiency: Atlas Copco GA Compressor Guide

In today's fast-paced industrial landscape, efficiency and sustainability are paramount. The Atlas Copco GA compressor stands as a beacon of innovation, revolutionizing how industries operate. This guide delves into the intricacies of the Atlas Copco GA compressor, exploring its features, real-world applications, and future potential, ensuring a comprehensive understanding of its role in enhancing industrial efficiency.

Compressors are the backbone of many industrial processes, responsible for reducing energy consumption and managing gases effectively. In industries such as oil and gas, manufacturing, and chemical production, the efficiency of these machines directly impacts operational costs and environmental sustainability. The Atlas Copco GA compressor emerges as a cutting-edge solution, offering advanced features that significantly enhance performance.

This guide introduces the Atlas Copco GA compressor, highlighting its unique capabilities and how it contributes to industrial efficiency. By exploring its design, functionality, and real-world applications, we aim to provide insights that can drive operational improvements and sustainability initiatives.

Understanding the Basics: Types of Compressors

Before diving into the specifics of the Atlas Copco GA compressor, it's essential to understand the broader landscape of compressor types. Compressors are categorized into several types based on their operational principles and applications:

Reciprocating Compressors: These include piston and rotary reciprocating compressors, known for their reliability and durability. They are widely used in industrial settings due to their ability to operate efficiently over a wide range of pressures.

Rotary Compressors: Such as scroll and centrifugal rotary compressors, these are known for higher efficiency and are often used in applications requiring precise control over compressed air.

Positive Displacement Compressors: These compressors, like the Atlas Copco GA, measure the volume of gas being compressed, ensuring efficient and consistent performance.

Each type has its strengths and applications, but the Atlas Copco GA stands out as a positive displacement compressor, renowned for its advanced features and reliability.

Maximizing Efficiency and Reliability: Key Features of the Atlas Copco GA Compressor

The Atlas Copco GA compressor is designed with efficiency and reliability in mind. Its key features include:

Advanced Control Systems: The compressor is equipped with intelligent control systems that optimize performance based on real-time data. This ensures minimal energy consumption and reduces operational wear and tear.

Energy Efficiency: The GA compressor incorporates energy-efficient technologies, such as variable speed drives and smart controls, which significantly reduce energy waste.

Durability and Maintenance: Built to last, the Atlas Copco GA is robust and designed for harsh industrial environments, with features that minimize downtime and extend lifespan.

These features not only enhance operational efficiency but also contribute to lower operational costs and reduced environmental impact.

Case Studies: Real-World Applications

To illustrate the effectiveness of the Atlas Copco GA compressor, real-world case studies are essential. For instance, a manufacturing facility implemented the GA compressor, resulting in a 20% reduction in energy consumption. Another client noted a 15% increase in production efficiency without compromising on compressor performance.

These case studies highlight how the Atlas Copco GA compressor can be tailored to specific industrial needs, delivering measurable benefits in energy savings and operational efficiency.

Comparative Analysis: GA vs. Other Compressors

When comparing the Atlas Copco GA compressor with other leading industrial compressors, its unique advantages become evident:

- Energy Efficiency: The GA's advanced controls and smart systems outperform traditional compressors in energy efficiency.

- Durability: Its robust design ensures longevity, reducing the need for frequent replacements.

- Innovation: The compressor incorporates cutting-edge technologies, setting it apart from competitors.

While other compressors may offer similar features, the Atlas Copco GA stands out due to its comprehensive approach to efficiency and reliability.

Sustainability and Environmental Impact

In today's environmentally conscious market, the Atlas Copco GA compressor plays a crucial role in sustainability. Its energy-efficient design and smart controls significantly reduce energy waste, contributing to a lower carbon footprint.

Additionally, the compressor's advanced technologies, such as better insulation and smart grids, further enhance its eco-friendly credentials, making it an ideal choice for sustainable industrial practices.

Future Trends: Innovations on the Horizon

Looking ahead, the compressor industry is poised for innovation, with emerging technologies like AI-driven compressors and smart grids transforming the landscape. The Atlas Copco GA is at the forefront of these developments, offering a glimpse into a future where compressors are smarter, more efficient, and more integrated with digital systems.

These future trends underscore the Atlas Copco GA's role as a leader in the industry, continually evolving to meet the demands of a rapidly changing world.

The Atlas Copco GA Compressor - A Pillar of Industrial Efficiency

In an era where efficiency and sustainability are paramount, the Atlas Copco GA compressor stands as an indispensable tool for industries worldwide. By offering advanced features, real-world success, and a commitment to innovation, the GA compressor not only enhances operational performance but also contributes to a greener future.

As the compressor industry evolves, the Atlas Copco GA remains a beacon of technological advancement, ensuring that industries continue to operate at their highest potential. Embrace the efficiency and reliability of the Atlas Copco GA compressor and join the ranks of industries that are reaping the benefits of cutting-edge technology.

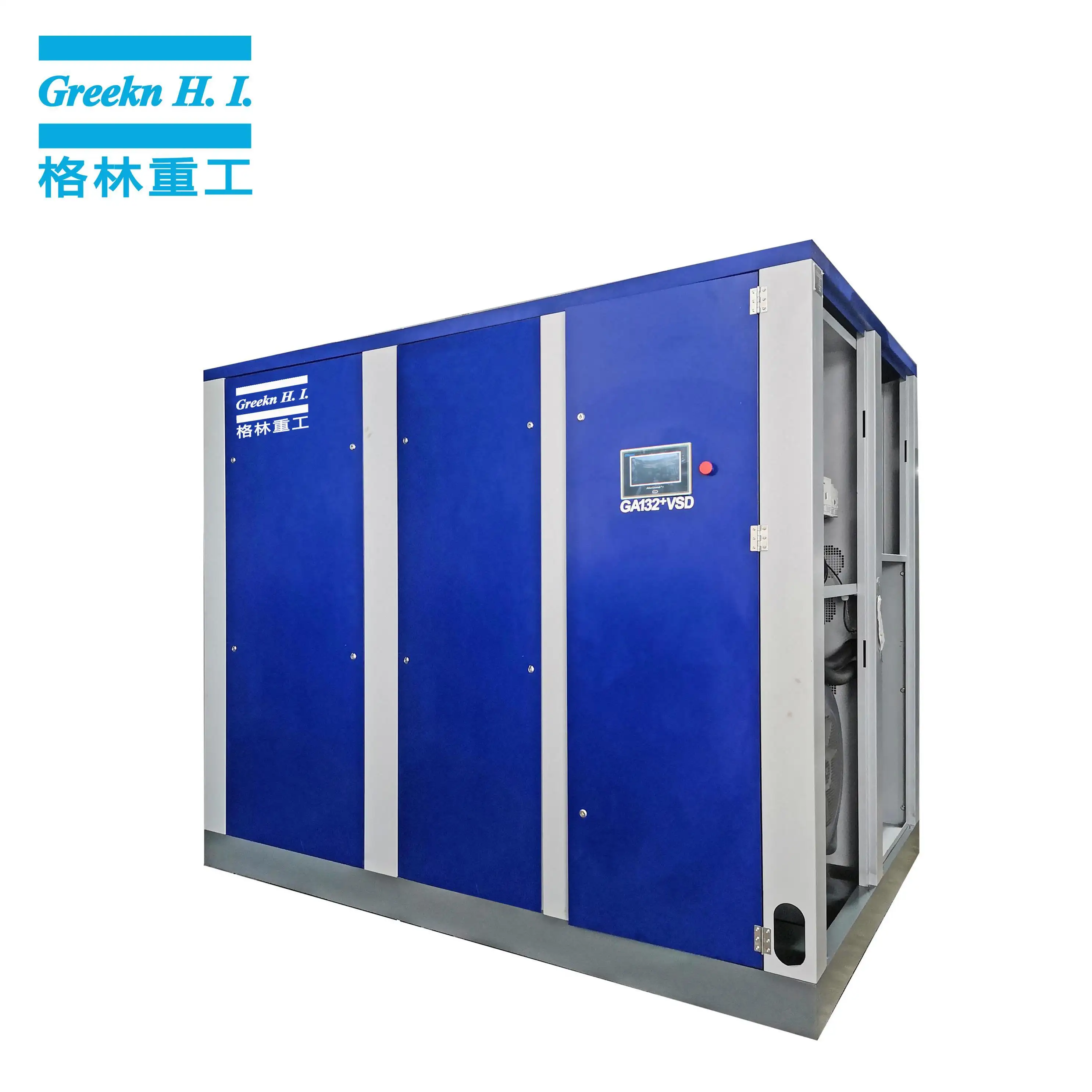

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.