Why Atlas Copco Screw Compressors are the Best Choice for Industrial Use

Understanding Screw Type Air Compression Technology

Screw type air compressors, developed by Atlas Copco, operate on a unique principle that sets them apart from traditional piston compressors. The technology involves the reciprocation of a cylindrical piston within a helical rotory chamber, which is driven by a motor. This design results in continuous airflow without pulsations, lower noise levels, and minimal leakage. The result is quieter, more efficient operations, making it ideal for industrial settings where noise control and efficiency are crucial.

Reliability and Durability: The Backbone of Atlas Copco Screw Compressors

At the heart of the Atlas Copco screw compressor lies its commitment to reliability and durability. Constructed with high-quality materials, these compressors withstand harsh industrial environments with ease. Regular maintenance, including oil filtering and lubrication, ensures optimal performance over the compressor's lifecycle. The robust design and advanced engineering contribute to a machine that delivers consistent output, minimizing downtime and maximizing productivity.

Energy Efficiency and Cost Savings

Energy efficiency is a key selling point for Atlas Copco screw compressors. Equipped with variable frequency drive systems, these compressors can adjust their speed to match the workload, optimizing energy consumption. Additionally, advanced oil management systems help reduce energy waste, making them a cost-effective choice for industrial users. The investment in energy efficiency translates to significant savings over the long term, reducing operational costs and enhancing profitability.

Advanced Features and Customization Options

Atlas Copco's screw compressors offer a range of customization options, catering to diverse industrial needs. Features such as modular designs, oil recovery systems, and remote monitoring capabilities allow for seamless integration into various processes. The ability to customize these compressors ensures they meet the specific requirements of each application, whether it's handling heavy-duty tasks or integrating with automation systems. This level of adaptability underscores the versatility of Atlas Copco products.

Maintenance and Service Support

Profound commitment to customer satisfaction is evident in Atlas Copco's maintenance and service programs. The company offers comprehensive services, including routine inspections, spare parts supply, and skilled technicians for on-site repairs. This level of support ensures that industrial users can rely on Atlas Copco for maintenance, minimizing unexpected breakdowns and maximizing operational efficiency.

Real-World Applications and Case Studies

The real-world applications of Atlas Copco screw compressors are vast and varied. From oil and gas exploration to construction and manufacturing, these compressors have proven their reliability and efficiency in challenging environments. Case studies highlight their ability to handle high-pressure, high-volume tasks with ease, contributing to operational success and reducing downtime. These proven applications further cement the reputation of Atlas Copco as a trusted industrial partner.

Comparative Analysis with Other Compressors

When comparing Atlas Copco screw compressors with other leading brands, several factors emerge as key advantages. The combination of efficiency, durability, and customization sets Atlas Copco apart. While other brands may offer similar features, it is Atlas Copco's commitment to innovation and customer support that distinguishes them. These advantages make Atlas Copco a preferred choice for demanding industrial applications.

Future Trends and Innovations

Looking ahead, Atlas Copco is at the forefront of technological advancements in air compression. The company is investing heavily in research and development, focusing on areas such as digitalization, sustainability, and energy efficiency. Innovations like smart monitoring systems and eco-friendly solutions are shaping the future of industrial air compression, ensuring that Atlas Copco remains a leader in this ever-evolving field.

Investing in Atlas Copco Screw Compressors for Unmatched Performance

In conclusion, Atlas Copco screw compressors offer unmatched performance, reliability, and versatility, making them an indispensable tool for industrial operations. From their advanced technology and energy-efficient design to their robust construction and comprehensive maintenance support, these compressors deliver exceptional value. For those seeking a trusted partner in their industrial journey, Atlas Copco is the clear choice. Invest in Atlas Copco screw compressors and experience the difference of world-class performance tailored to your needs.

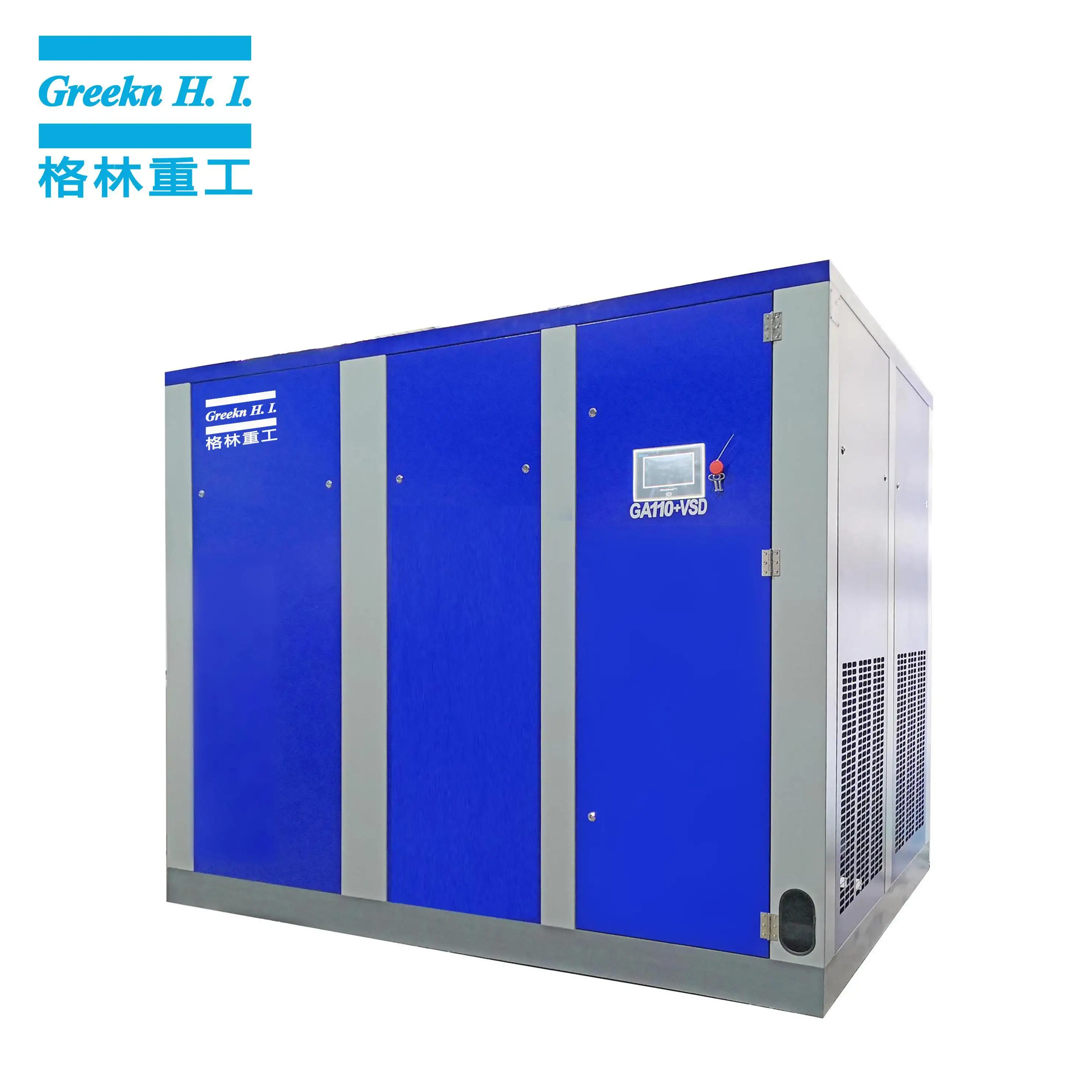

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.