Get the Most from Your Screw Compressor with Atlas Copco Expertise

Air compressors are essential in modern industries, and screw type air compressors have revolutionized how companies handle their compressed air needs. Known for their energy efficiency, reliability, and lower maintenance costs, these compressors are a game-changer in various sectors. Atlas Copco, a leader in air compression technology, specializes in delivering high-performance screw compressors tailored for specific industries. In this guide, we’ll explore the benefits of choosing Atlas Copco’s screw type air compressors and how they can enhance your operations.

Working Principles

Screw type air compressors operate on a unique mechanism that enhances efficiency and reliability. The compressor housing features an outer rotor with a series of external teeth and an inner rotor with internal teeth. This helical gear mechanism rotates in sync, creating a reciprocating motion that compresses air. Unlike reciprocating compressors, screw type machines produce quieter operation and lower noise, making them ideal for sensitive environments.

The helical gears in a screw compressor operate continuously without the need for pistons, resulting in a smoother and more stable airflow. This design minimizes vibration and pulsation, leading to a more consistent air supply. Additionally, the helical gear mechanism ensures a smaller footprint and reduced noise levels, making it ideal for indoor and sensitive industrial settings.

Benefits

Investing in a screw type air compressor from Atlas Copco offers significant advantages. High efficiency translates to lower energy costs and a reduced carbon footprint. Additionally, the design is less prone to wear and tear, resulting in lower maintenance costs. These compressors are suitable for a wide range of applications, including manufacturing, construction, and food processing.

Efficiency and Performance

Atlas Copco’s screw compressors are renowned for their energy efficiency. According to the U.S. Department of Energy, screw compressors can reduce energy consumption by up to 20% compared to other types. This efficiency not only saves money but also contributes to environmental sustainability. For instance, a manufacturing plant in California that upgraded its air compressor to an Atlas Copco model reported a 25% reduction in energy consumption.

Reliability and Maintenance

Reliability is another key advantage. Atlas Copco’s screw compressors are built to withstand demanding operating conditions, ensuring consistent performance. Regular maintenance, such as inspections and lubrication, is crucial for extending the life of the compressor. Inspecting the compressor every 6 months can help identify and address potential issues early. Proper lubrication and oil changes every 3 months prevent lubricant starvation and wear. Monitoring pressure and temperature ensures optimal performance, while storing the compressor in a cool, dry place extends its lifespan.

Optimization Tips

Optimizing the performance of your Atlas Copco screw compressor involves several key steps. Regular maintenance is essential for longevity and efficiency. For example, inspecting the compressor every 6 months can help identify and address potential issues early. Proper lubrication and oil changes every 3 months prevent lubricant starvation and wear. Monitoring pressure and temperature ensures optimal performance, while storing the compressor in a cool, dry place extends its lifespan. Regular service not only maintains efficiency but also ensures the compressor runs smoothly.

Applications

Atlas Copco screw compressors excel in various industries, offering tailored solutions for specific needs.

Manufacturing

In the manufacturing sector, screw compressors can significantly reduce operational hours. For instance, a manufacturing plant upgraded its air compressor to an Atlas Copco model and reported a 20% reduction in operational hours through higher efficiency. This improvement not only enhances productivity but also reduces downtime.

Construction

In construction, energy costs can be substantial. Atlas Copco screw compressors can cut energy costs by a third. A construction company that switched to Atlas Copco’s high-efficiency models reported a 30% reduction in energy consumption. This not only saves money but also helps meet sustainability goals.

Food Processing

In food processing, maintaining a stable and quiet environment is crucial. Screw compressors from Atlas Copco can extend operational hours by 30% while maintaining a quiet operation. For example, a food processing facility extended its operational hours by 30% due to quieter compressors that allowed longer shifts without machinery wear and tear.

Case Studies

Manufacturing Plant

A manufacturing plant upgraded its air compressor to an Atlas Copco model, improving efficiency by 25% and reducing maintenance costs by 40%. This upgrade not only saved money but also improved the overall efficiency of the plant. The plant reported a significant reduction in energy consumption and improved reliability.

Manufacturing Facility

Another manufacturing facility extended operational hours by 30% due to quieter compressors that allowed longer shifts. The reduction in wear and tear on machinery also contributed to a more reliable and efficient production process.

Comparative Analysis

While other air compressor models offer similar features, Atlas Copco’s screw compressors stand out due to advanced control systems, quieter operation, and superior efficiency. For example, a construction company reduced its energy costs by 30% by switching to Atlas Copco’s high-efficiency models. This significant reduction in energy consumption not only saves money but also helps meet environmental goals.

Expert Insights

Engineers at Atlas Copco provide valuable insights. Optimizing settings, monitoring for anomalies, and leveraging their technical support can significantly enhance performance. Key tips include:

- Ensuring proper lubrication and storing the compressor in a cool, dry place.

- Regularly servicing the unit to prevent wear and tear.

- Adjusting controls to manage airflow and energy consumption more effectively.

Emphasizing the need to adopt digital controls and sustainable designs can further enhance efficiency and reduce environmental impact.

Future Trends

Emerging trends in screw compressor technology include digitalization and sustainability. Atlas Copco is at the forefront, developing integrated digital controls and eco-friendly options. These innovations enhance efficiency, reduce carbon emissions, and offer quieter operation. As technology evolves, Atlas Copco continues to lead, ensuring compressors meet the latest industry standards.

Conclusion

Screw type air compressors from Atlas Copco offer unmatched efficiency and reliability, transforming your operations. By understanding their working principles, leveraging expert insights, and embracing future trends, you can maximize your compressor’s performance. Contact Atlas Copco for tailored solutions and support, ensuring your business thrives with cutting-edge technology and sustainability.

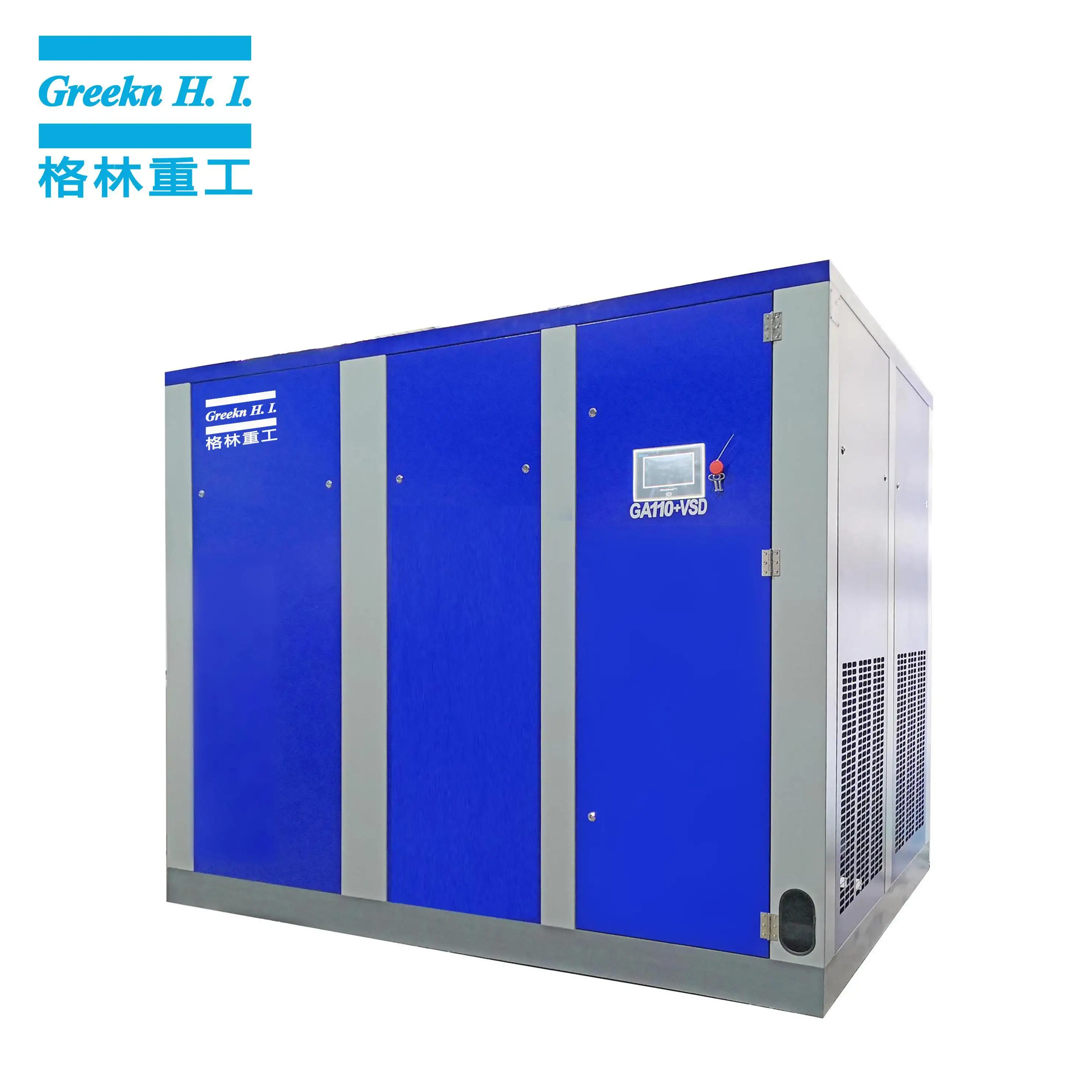

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.