Variable Speed Air Compressors: The Ultimate Choice for Versatility

In today’s fast-paced industrial and commercial environments, air compressors are indispensable tools that drive efficiency and productivity. Unlike traditional fixed-speed air compressors, variable speed air compressors have emerged as a game-changer, offering unparalleled flexibility and energy efficiency. As industries continue to demand innovative solutions, variable speed air compressors are becoming the preferred choice for businesses looking to optimize their operations.

The concept of variable speed air compressors revolves around the ability to adjust the speed of the compressor motor based on the demand for air. This intelligent technology allows these compressors to operate at varying speeds, which means they can be more efficient, reduce energy consumption, and minimize operational costs. Whether you’re running a small manufacturing plant or a large construction company, variable speed air compressors are designed to adapt to your needs, ensuring maximum productivity and cost-effectiveness.

Understanding Variable Speed Air Compressors

Variable speed air compressors are a type of positive displacement compressor that uses a rotary piston or a scroll compressor to compress air. What sets them apart from traditional models is their ability to adjust their speed dynamically. This adjustment is achieved through advanced control systems that monitor the compressor’s workload and automatically increase or decrease the speed to match demand.

The core components of a variable speed air compressor include the compressor housing, motor, speed control system, cooling system, and air delivery system. The housing is designed to protect the motor and other internal components from harmful air contaminants. The motor is equipped with a speed control system that allows it to adjust its RPM based on the compressor’s load. The cooling system ensures that the motor remains operational by removing excess heat, while the air delivery system distributes the compressed air to meet the needs of the application.

Understanding how variable speed air compressors work is essential to grasping their benefits. These compressors are designed to handle varying workloads, from light tasks to heavy-duty operations, making them ideal for industries that require flexibility. Unlike fixed-speed compressors, which run at a constant speed regardless of demand, variable speed compressors can adjust to the specific needs of the operation, reducing energy waste and extending the lifespan of the equipment.

Benefits of Variable Speed Air Compressors

One of the most significant advantages of variable speed air compressors is their ability to improve energy efficiency. By adjusting the speed of the compressor based on demand, these machines can significantly reduce energy consumption. In fact, variable speed compressors can save up to 30% on energy costs compared to fixed-speed models. This cost-saving potential is particularly beneficial for businesses looking to reduce their operational expenses.

Another key benefit of variable speed air compressors is their capacity to extend the lifespan of equipment and reduce maintenance. Since these compressors are designed to operate at optimal speeds for their workload, they are less likely to overheat or experience wear and tear. This extended equipment life not only reduces the need for frequent maintenance but also minimizes the risk of breakdowns, ensuring consistent performance over the long term.

Precision control is another advantage of variable speed air compressors. These machines are equipped with advanced control systems that allow for fine adjustments to the compressor’s speed. This level of control is essential for industries that require precise air pressure control, such as hydraulics, pneumatics, and electronic packaging. By maintaining consistent air pressure, variable speed compressors ensure optimal performance for downstream applications.

In addition to these technical advantages, variable speed air compressors also offer enhanced performance in a variety of applications. Whether you’re compressing air for industrial manufacturing, power generation, or even for recreational purposes, these compressors are designed to handle the demands of the job. Their versatility makes them a valuable asset for businesses of all sizes and industries.

Applications in Diverse Industries

Variable speed air compressors are not limited to industrial settings; they are also finding applications in a wide range of industries. From manufacturing and construction to automotive and healthcare, these compressors are proving to be indispensable in today’s interconnected world.

In manufacturing, variable speed air compressors are essential for processes such as metalworking, welding, and painting. These operations often require precise control over air pressure, and the ability to adjust the compressor’s speed allows manufacturers to optimize their production processes. By reducing energy consumption and improving efficiency, variable speed compressors help manufacturers meet stringent environmental regulations and reduce their carbon footprint.

In the automotive industry, variable speed air compressors are used for tasks such as tire inflation, air conditioning, and engine cooling. The ability to adjust the compressor’s speed ensures consistent air pressure, which is critical for the performance and safety of vehicles. Additionally, the energy efficiency of variable speed compressors helps reduce fuel consumption and lower operational costs for automotive companies.

Construction and civil engineering projects also benefit from the use of variable speed air compressors. Whether you’re compressing air for concrete mixing, soil compaction, or excavation, these compressors provide the precision and reliability needed to get the job done. Their variable speed operation allows construction companies to adapt to the varying demands of their projects, ensuring efficiency and productivity.

In the healthcare sector, variable speed air compressors are used for medical equipment, such as deflating air beds or compressing medical gases. The ability to control air pressure with precision is critical in medical applications, where safety and effectiveness are paramount. Variable speed compressors also contribute to energy efficiency, helping healthcare facilities reduce their operational costs and reduce their environmental impact.

Comparative Analysis: Variable Speed vs. Fixed Speed Compressors

To fully appreciate the benefits of variable speed air compressors, it’s important to compare them to fixed-speed compressors and understand the differences between the two.

Fixed-speed air compressors run at a constant speed, regardless of the workload. This means that they either operate at maximum capacity when there is high demand or at minimum capacity when there is low demand. While fixed-speed compressors are simpler and less expensive to purchase, they are not as energy-efficient or adaptable as variable speed models.

On the other hand, variable speed compressors are designed to adjust their speed based on the demand for air. By doing so, they can optimize energy usage and reduce waste. Variable speed compressors are more complex and expensive to purchase, but they offer significant cost savings and performance improvements over fixed-speed models in the long run.

One of the key differences between variable speed and fixed-speed compressors is their ability to handle varying workloads. Variable speed compressors can adjust their speed to match the demand, ensuring that they are never running at maximum capacity when there is low demand. This not only improves energy efficiency but also reduces the risk of equipment damage from overloading.

Fixed-speed compressors, on the other hand, are designed for specific applications and cannot adjust to changing conditions. While they are reliable and durable, they are not as versatile or energy-efficient as variable speed models. In industries where workload demands are unpredictable or fluctuating, fixed-speed compressors may not be the best choice.

Another important consideration when comparing variable speed and fixed-speed compressors is their maintenance requirements. Variable speed compressors, due to their advanced control systems, may require more specialized maintenance and tuning. This can make them more expensive to operate in the long term, although the initial cost savings from energy efficiency often offset these costs.

Fixed-speed compressors are generally easier to maintain and require less specialized knowledge, making them a more accessible option for smaller businesses or individuals who are not experienced in handling industrial equipment. However, their lack of adaptability and lower energy efficiency make them less suitable for industries that demand high levels of flexibility and precision.

In summary, variable speed air compressors offer a more efficient, adaptable, and cost-effective solution for businesses that require high levels of versatility. While they may require more upfront investment and maintenance, the long-term benefits of energy savings and performance improvements make them an essential tool for any industry.

Future Trends and Innovations

The world of air compressors is constantly evolving, and variable speed air compressors are no exception. As technology advances, we can expect to see further innovations in the design and functionality of these compressors, enabling them to meet the demands of an ever-changing world.

One of the most promising areas of innovation is the use of smart controls and AI to optimize the performance of variable speed air compressors. By integrating sensors and real-time data analysis, these compressors can automatically adjust their speed and operation based on environmental conditions, energy prices, and production demands. This level of intelligence will make variable speed compressors even more energy-efficient and adaptable, ensuring that they remain at the forefront of technological advancement.

Another exciting development is the use of predictive maintenance and advanced monitoring systems. By analyzing data from the compressor’s operation, businesses can predict when maintenance is needed and take proactive steps to prevent equipment failures. This not only improves the reliability of variable speed compressors but also extends their lifespan, reducing downtime and maintenance costs.

In addition to these technological advancements, the environmental benefits of variable speed air compressors are expected to grow as industries prioritize sustainability. By reducing energy consumption and lowering carbon emissions, variable speed compressors will play a key role in helping businesses meet global environmental standards. As companies continue to adopt more sustainable practices, variable speed compressors will become an essential tool for reducing their environmental impact.

Why Choose Variable Speed Air Compressors?

In an era where efficiency, adaptability, and sustainability are increasingly important, variable speed air compressors have emerged as the ultimate solution for businesses looking to optimize their operations. By offering energy efficiency, precision control, and versatility, these compressors are transforming the way industries approach air compression needs.

Whether you’re running a small-scale operation or a large-scale manufacturing facility, variable speed air compressors provide the flexibility and power to meet your demands. With their advanced control systems, innovative technologies, and commitment to sustainability, these compressors are not only a cost-effective choice but also a forward-looking investment in your business’s future.

As industries continue to demand more from their equipment, variable speed air compressors are the perfect answer. By embracing the benefits of variable speed technology, businesses can reduce costs, improve efficiency, and pave the way for a more sustainable and innovative future. It’s time to choose a variable speed air compressor and take the first step toward a more efficient, adaptable, and sustainable tomorrow.

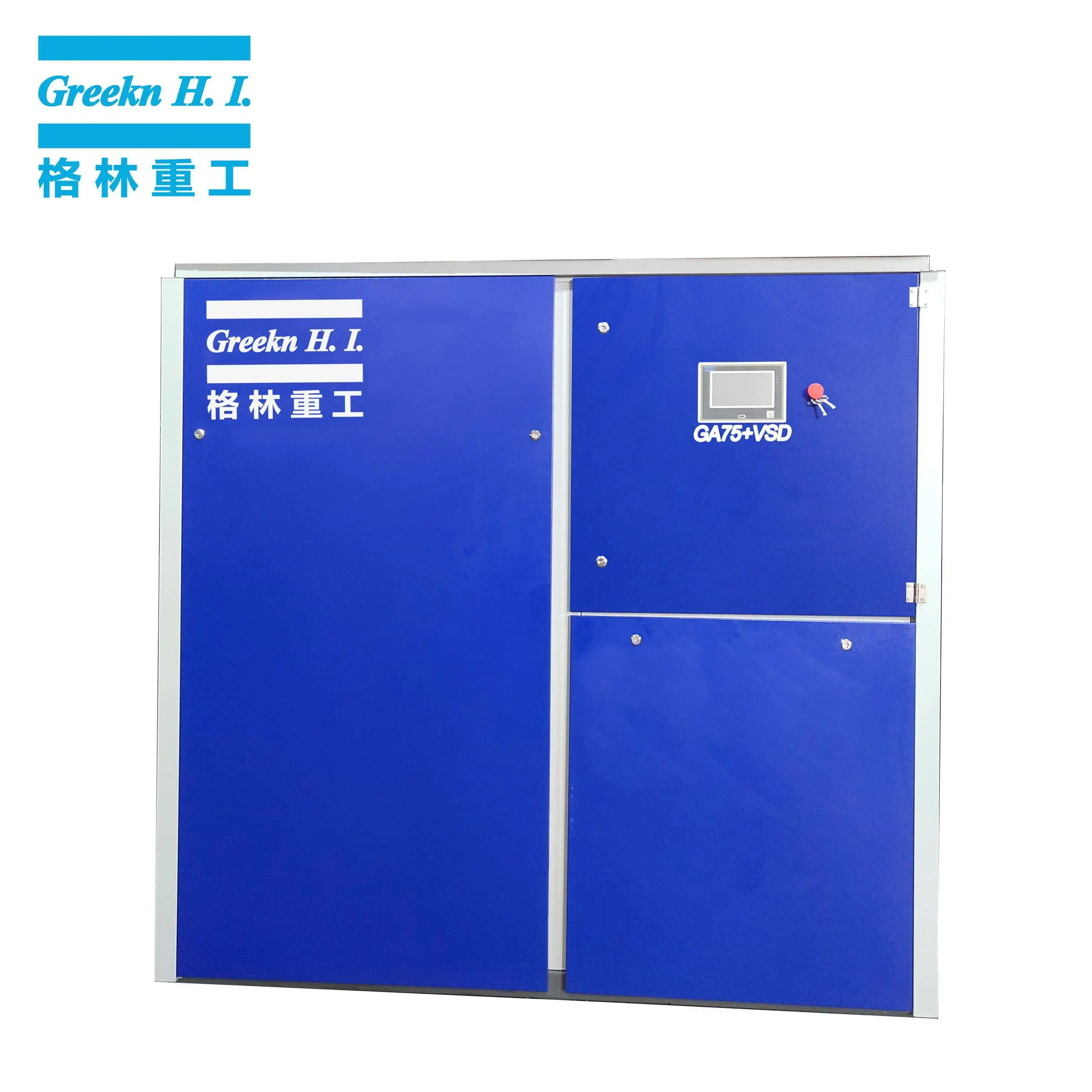

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.