The Science Behind Fixed Speed Rotary Screw Compressors

Fixed speed rotary screw compressors are integral to industries requiring steady gas compression. Unlike variable speed compressors, these machines maintain a constant output, making them ideal for demanding applications. Their robust and reliable design ensures consistent performance, making them a go-to solution in manufacturing, food processing, and automotive sectors.

Principles of Operation

The operation of fixed speed rotary screw compressors involves a few key stages: intake, compression, and discharge. Let's break down each stage for better clarity.

Intake Stage

During the intake stage, gas enters the designated chamber through an intake valve. The rotor blades then trap and move the gas towards the center of the casing.

Compression Stage

As the rotor continues to spin, the trapped gas is pushed towards the casing's center, where the volume decreases. This compression occurs due to the difference in volume between the intake and discharge stages, significantly increasing the gas pressure.

Discharge Stage

The compressed gas is then channeled through the discharge valve and into the system. The process is continuous, ensuring a consistent output of high-pressure air.

Advantages of Fixed Speed Compressors

Fixed speed compressors offer several advantages, making them a preferred choice for many industries.

Consistent Output

Maintaining a steady pressure and flow ensures reliable operation in critical processes.

High Efficiency

These compressors are efficient at full load, reducing energy consumption and start-up times.

Lower Maintenance Costs

They require less frequent maintenance compared to variable speed compressors, reducing downtime and associated costs.

Comparative Analysis with Variable Speed Compressors

Variable speed compressors offer flexibility and energy efficiency but require additional startup costs and monitoring. Fixed speed compressors provide predictable performance at a lower cost, making them more cost-effective for steady operations.

Energy Consumption

Variable speed compressors are more energy-efficient as they can adjust their speed to match demand, reducing power consumption. Fixed speed compressors, being constant, use more energy even when the demand is low.

Flexibility

Variable speed compressors offer better adaptability to varying demands, making them suitable for industries with fluctuating usage patterns.

Initial Cost and Maintenance

Variable speed compressors have higher initial installation costs and require more frequent maintenance due to their sophisticated control systems. Fixed speed compressors have a lower initial cost and demand less maintenance.

Applications and Industries

Fixed speed compressors are widely used in manufacturing, food processing, and automotive industries. Their efficiency and reliability make them a staple in these sectors.

Key Applications

- Manufacturing: Used in pneumatic tools, material handling, and process control.

- Food Processing: Essential for gas compression in preservation, sealing, and packaging.

- Automotive: Involved in the production of braking systems, air conditioning, and other critical functions.

Maintenance and Troubleshooting

Regular maintenance is crucial for optimal performance. Key practices include oil changes, temperature monitoring, and seal replacements.

Maintenance Practices

- Oil Changes: Prevent wear and tear, ensuring longevity.

- Temperature Monitoring: Prevent overheating, which can damage components.

- Seal Replacement: Maintain tight seals and prevent leaks.

Future Trends and Innovations

Emerging technologies aim to enhance fixed speed compressors' efficiency and durability. Innovations such as advanced rotor designs and smarter lubrication systems promise to reduce energy consumption and maintenance costs.

Future Innovations

- Advanced Rotor Designs: Improve compression efficiency and reduce noise.

- Smarter Lubrication Systems: Enhance energy efficiency and extend the lifespan of the compressor.

- Advanced Materials: Strengthen durability and reduce wear and tear.

Conclusion

Fixed speed rotary screw compressors are indispensable in modern industries, offering a balance of efficiency and reliability. As technology advances, these compressors will continue to play a pivotal role, with innovations enhancing their performance and adaptability. Understanding their principles, benefits, and future potential equips readers to make informed decisions and optimize industrial processes.

By comprehensively understanding fixed speed rotary screw compressors, you can better appreciate their significance in various applications. These compressors are more than just machines—they are the backbone of many industrial processes, enabling consistent and reliable performance in critical operations.

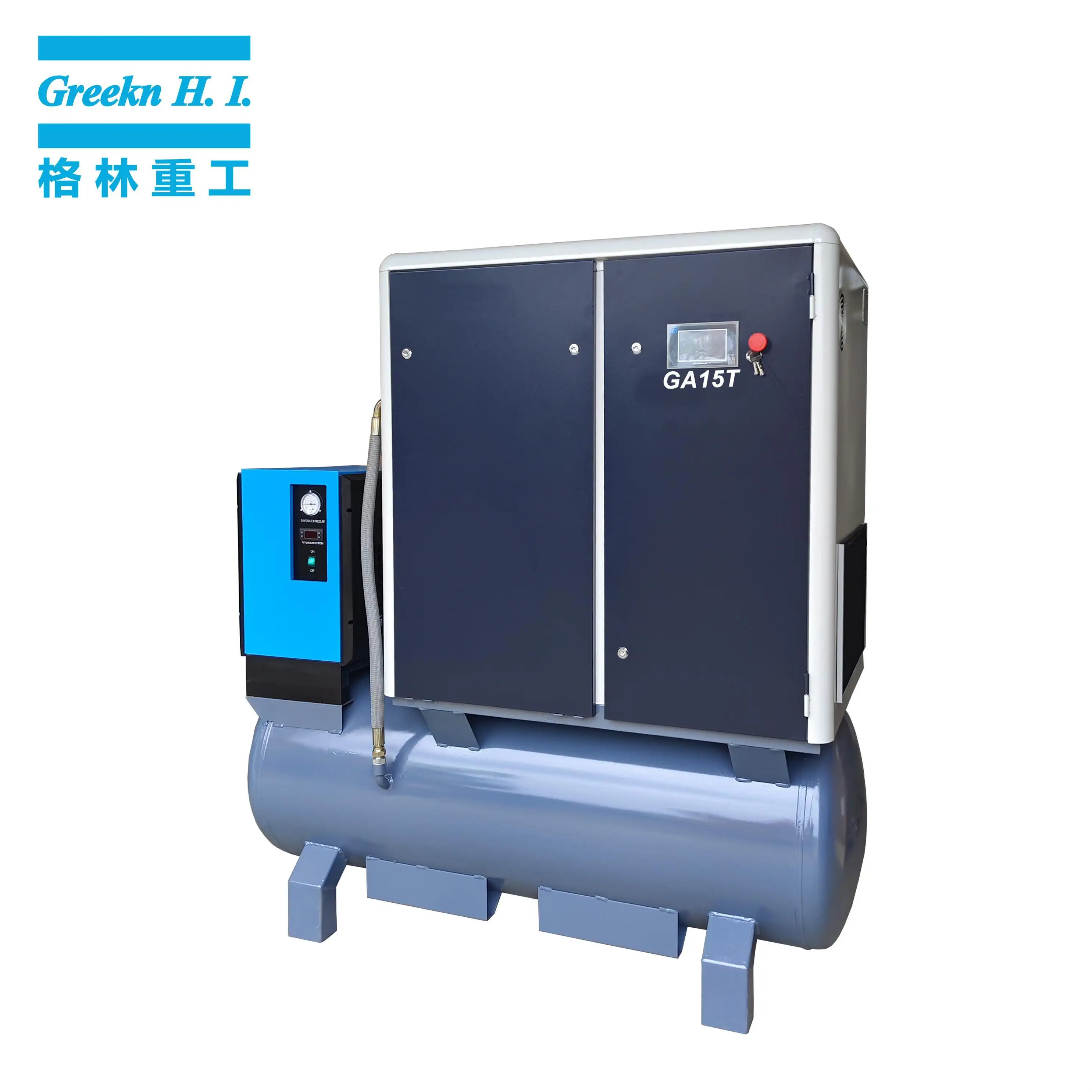

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.