Next-Gen Air Compressors: Exploring the Advantages of Variable Speed Drives

Understanding Variable Speed Drive Air Compressors

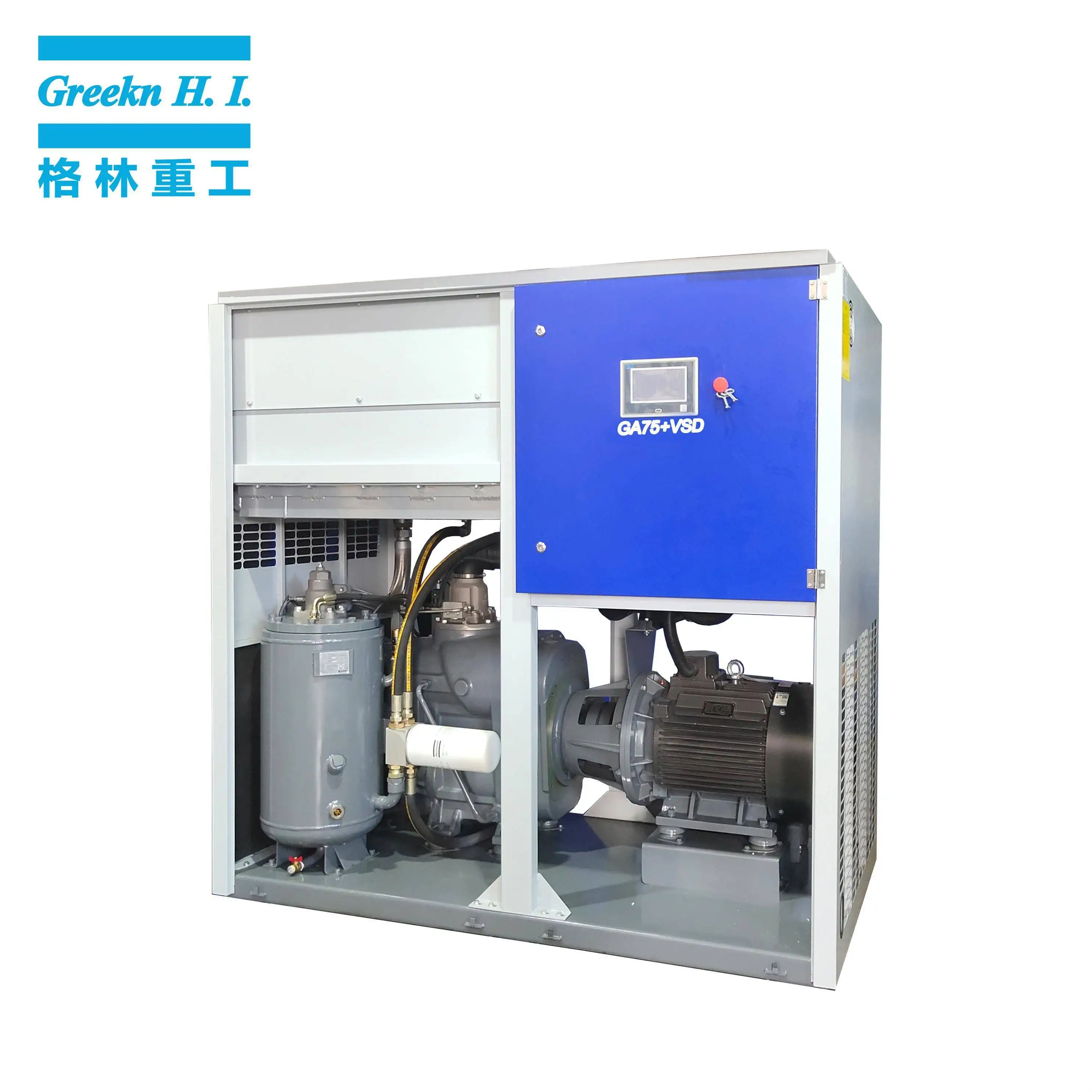

Variable Speed Drive (VSD) air compressors operate on the principle of adjusting the motor speed via an inverter, allowing precise control over air flow. Unlike traditional air compressors with fixed speeds, VSD technology offers enhanced performance, durability, and cost-effectiveness. By integrating intelligent control systems, VSD air compressors provide a dynamic approach to air supply, making them ideal for fluctuating demand scenarios.

Efficiency and Energy Savings: The Core Advantage of VSD Technology

VSD air compressors revolutionize energy efficiency, reducing operational costs and environmental impact. By optimizing air flow, VSD systems minimize energy waste, lowering power consumption by up to 20% compared to traditional setups. This efficiency not only extends equipment life but also contributes to a more sustainable future, making VSD a key component in the push towards green manufacturing.

Maintenance and Longevity: Redefined with VSDs

The adoption of VSD technology significantly enhances equipment longevity. Reduced wear and tear on components decrease maintenance costs and downtime, ensuring consistent performance over extended periods. This reliability is particularly beneficial for industries relying on continuous operation, such as automotive and energy sectors, where uptime is critical.

Versatility and Application Flexibility

VSD air compressors cater to diverse industries, offering adaptable solutions. From automotive to manufacturing, these systems optimize performance based on specific needs. Their ability to handle varying workloads and environmental conditions makes them a versatile choice, ensuring efficiency across different operational settings.

Comparative Analysis: Traditional vs. VSD Air Compressors

A direct comparison reveals the superior performance of VSD air compressors. Traditional systems often struggle with energy inefficiency and wear, whereas VSDs offer precise control, reducing energy consumption and extending equipment life. Metrics such as energy efficiency and operational flexibility underscore VSD's advantages, making it a preferred choice for modern industrial setups.

Case Studies: Real-World Examples of VSD Air Compressors in Action

Real-world implementations highlight VSD air compressors' impact. By reducing energy costs by 15% and extending equipment lifespan, companies have achieved significant improvements. These case studies demonstrate how VSD technology can lead to substantial savings and operational efficiencies, solidifying its role as an industry advancement.

Future Trends and Technological Advancements

Emerging trends like smart integration and predictive maintenance further enhance VSD technology. These advancements promise even greater efficiency and automation, positioning VSD air compressors at the forefront of intelligent manufacturing solutions.

Embracing the Future of Air Compressor Technology

In conclusion, VSD technology represents a significant leap forward in air compressor innovation. By enhancing efficiency, reducing costs, and minimizing environmental impact, VSD air compressors are poised to dominate the industry. Encouraging businesses to adopt this technology is not just an investment; it's a step towards a more sustainable and efficient future. Transitioning to VSD-driven systems can be a strategic move towards meeting industry demands and achieving long-term operational excellence.

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.