Compressed Air Dryers and Energy Efficiency: Strategies and Solutions

Compressed air systems are everywhere in industry, from automotive manufacturing to pharmaceuticals. These systems are essential for driving pneumatic tools, operating hydraulic cylinders, and controlling various automated processes. The efficiency and reliability of these systems directly impact operational costs and productivity. Yet, they often suffer from moisture-related issues that can diminish their performance. Compressed air dryers are the key to overcoming these challenges.

The Role of Compressed Air Dryers in Energy Efficiency

Moisture in compressed air can lead to a myriad of problems. It can cause corrosion, reduce compressor efficiency, and degrade the lifespan of components. This moisture must be removed to ensure optimal system performance. Compressed air dryers are designed to remove moisture through various methods, such as adsorption, refrigeration, and desiccant absorption.

- Adsorption Dryers: These dryers use air to dry wet air, creating a continuous cycle. They are cost-effective but may require more frequent maintenance.

- Refrigerated Dryers: These dryers cool the air to a dew point below the moisture content, condensing and removing the moisture. They offer higher efficiency but come with higher maintenance costs.

- Desiccant Dryers: These dryers use a drying agent, typically silica gel, to absorb moisture from compressed air. They offer higher efficiency and reliability but are more expensive to purchase and maintain.

Understanding the advantages and limitations of each type of dryer is crucial for selecting the right one for your specific application.

Strategies for Optimizing Performance

Choosing the right type of dryer is only part of the solution. Effective maintenance and monitoring are equally important. Regular inspections, monitoring humidity levels, and scheduling timely maintenance can prevent breakdowns and reduce energy waste.

- Regular Inspections: Regular checks can identify potential issues before they become major problems.

- Monitoring Humidity Levels: Continuous monitoring ensures that the system is working within optimal ranges.

- Scheduling Timely Maintenance: Preventive maintenance can extend the life of the dryer and improve overall system efficiency.

Comparative Analysis of Energy Efficiency

Different dryer technologies vary in energy efficiency, maintenance costs, and environmental impact. Let's take a closer look at each type:

- Adsorption Dryers: Cost-effective initially, but may require more frequent maintenance. Example: An industry saw a 15% reduction in energy costs after switching from a standard dryer to an adsorption dryer.

- Refrigerated Dryers: Offer higher efficiency but come with higher maintenance costs. Example: A food processing plant improved its energy efficiency by 25% by upgrading to a refrigerated dryer.

- Desiccant Dryers: Balanced cost and efficiency, making them suitable for many applications. Example: An automotive manufacturing plant achieved a 20% reduction in operational costs by switching to desiccant dryers.

Using these comparisons, you can make an informed decision that fits your specific needs and budget.

Real-World Case Studies

Industry case studies illustrate the transformative impact of energy-efficient dryers. Here are a couple of examples:

1. Manufacturing Plant:

- Challenge: High energy costs and equipment failures due to excessive moisture.

- Solution: Upgraded to a more efficient dryer system.

- Results: Saw a 20% reduction in energy costs and a 15% increase in production.

- Facility Upgrade:

- Challenge: Old dryer technology leading to higher maintenance costs and inefficiencies.

- Solution: Replaced an older dryer with a more advanced model.

- Results: A 30% improvement in energy efficiency and a 10% reduction in maintenance costs.

These case studies demonstrate how careful selection and maintenance of dryers can lead to significant operational benefits.

Technological Innovations and Future Trends

The future of compressed air dryers is exciting with the integration of smart controls and IoT (Internet of Things) technologies. These advancements allow real-time monitoring and adjustment, optimizing drying processes. Here are some recent trends:

- Smart Controls: These systems provide real-time data on humidity levels and system performance, enabling proactive maintenance.

- IoT Integration: By connecting dryers to a network, facility managers can monitor and manage systems remotely.

As technology continues to advance, the potential for even greater energy efficiency in compressed air systems grows.

Conclusion

Compressed air dryers are essential for energy efficiency, making them indispensable in modern industrial operations. By understanding the impact of moisture, implementing effective strategies, and keeping up with technological advancements, industries can significantly enhance their efficiency. To get started, consider upgrading your compressed air system today to leverage advanced drying technologies. The benefits are clear: substantial savings, improved performance, and a cleaner environment.

Remember, the key is to choose the right type of dryer for your specific needs and maintain it effectively to maximize energy efficiency. Embrace the future of compressed air drying to drive your organization's success.

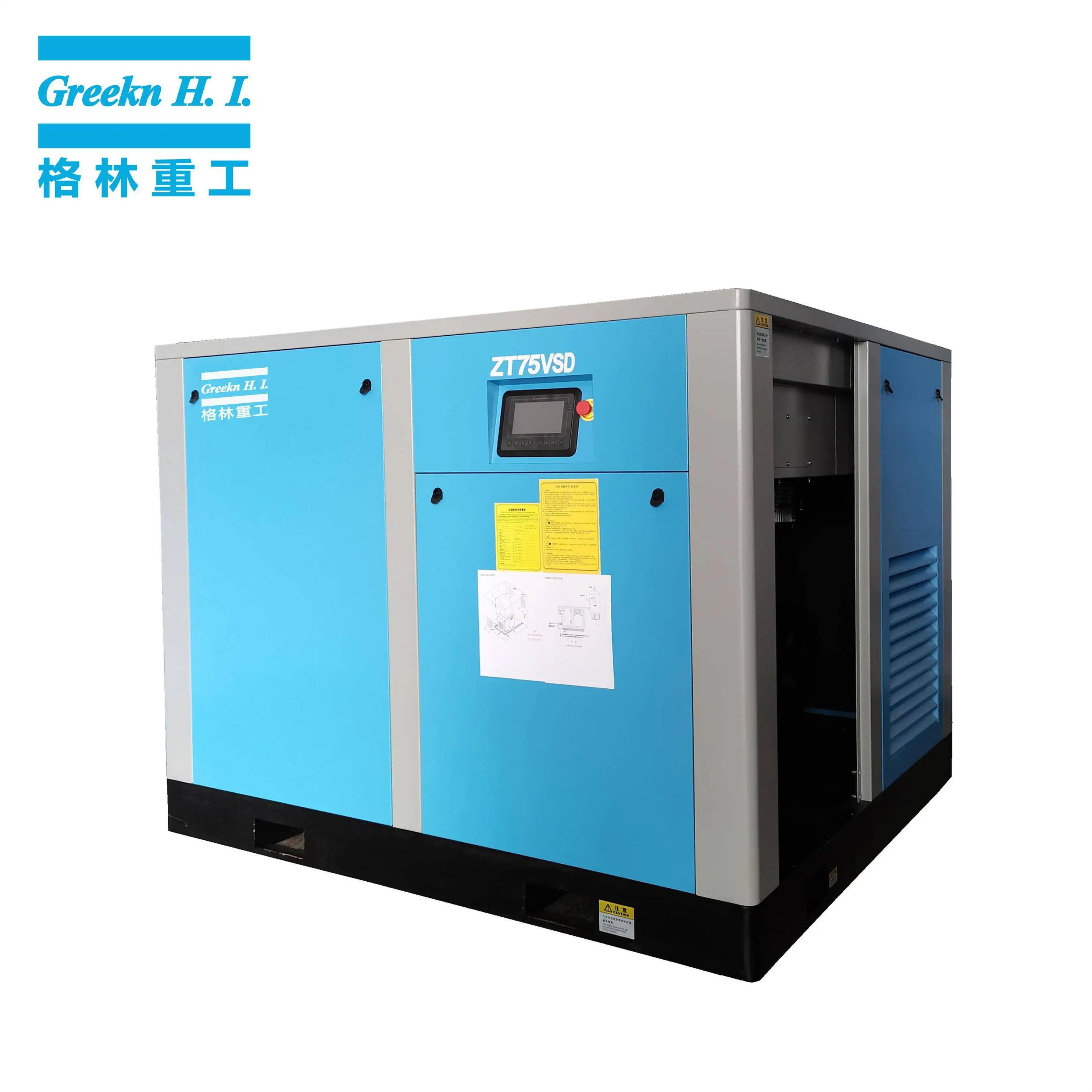

Greeknhi is committed to the research and development,design, production,sales,installation, repair,maintenance and technical engineering consulting services of efficient and energy-saving air compression system and compressed air purification equipment.The main products of the company are screw air compressor,air dryer,air receiver tank,etc...

E-mail: joanna@greeknhi.com

Address: No. 1021 West Yifeng Road,Quangang District,Quanzhou,China.